Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Throttle/pedal position

sensor/switch ”a” circuit / Inspection procedure

Toyota Corolla (E120): Inspection procedure

Hint

:

- if different dtcs related to different systems that have terminal e2 as the ground terminal are output simultaneously, terminal e2 may be open.

- Read freeze frame data using the hand-held tester or the obd ii scan tool. Freeze frame data records the engine conditions when a malfunction is detected. When troubleshooting, it is useful for determining whether the vehicle was running or stopped, the engine was warmed up or not, the air–fuel ratio was lean or rich, etc. At the time of the malfunction.

Hand–held tester:

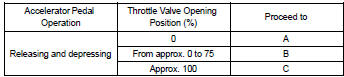

1 Read value of hand–held tester(throttle valve opening percentage)

- Connect the hand–held tester to the dlc3.

- turn the ignition switch on.

- select the item ”diagnosis / enhanced obd ii / data list / etcs / throttle pos” and read its value displayed on the hand–held tester.

Result:

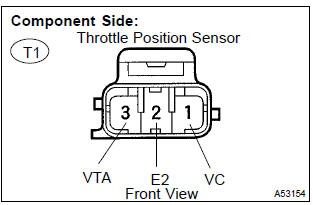

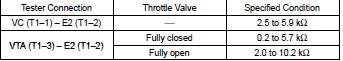

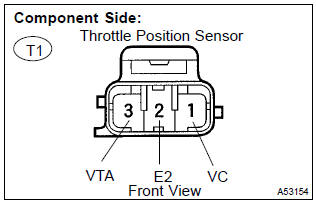

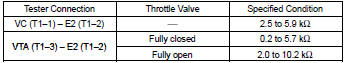

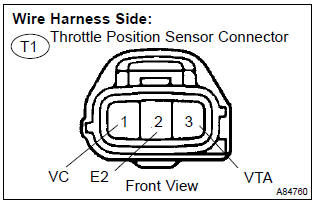

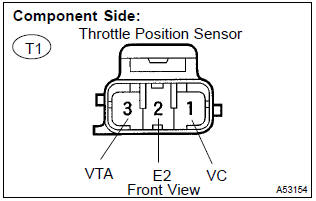

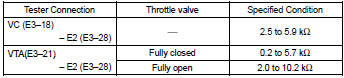

2 Inspect throttle position sensor

- Disconnect the t1 throttle position sensor connector.

- measure the resistance between the terminals of the throttle position sensor.

Standard

- Reconnect the throttle position sensor connector.

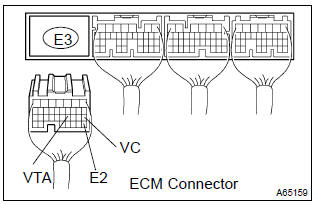

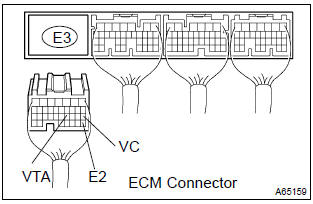

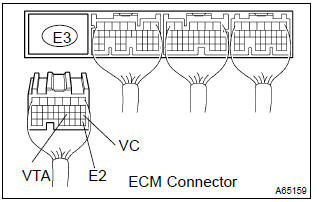

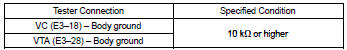

3 Check harness and connector(ecm – throttle position sensor)

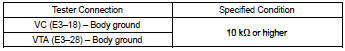

- Disconnect the e3 ecm connector.

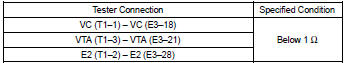

- measure the resistance between the terminals of the e3 ecm connector.

Standard:

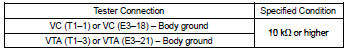

- Check the resistance between the terminals of the e3 ecm connector.

Standard (check for short):

- Reconnect the ecm connector.

Replace ecm

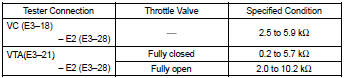

4 Inspect throttle position sensor

- Disconnect the t1 throttle position sensor connector.

- measure the resistance between the terminals of the throttle position sensor.

Standard:

- Reconnect the throttle position sensor connector.

5 Check harness and connector(ecm – throttle position sensor)

- Disconnect the e3 ecm connector.

- disconnect the t1 throttle position sensor connector.

- check the resistance between the wire harness side connectors.

Standard (check for open):

Standard (check for short):

- Reconnect the throttle position sensor connector.

- reconnect the ecm connector.

Replace ecm

Obd ii scan tool (excluding hand–held tester):

1 Inspect throttle position sensor

- Disconnect the t1 throttle position sensor connector.

- measure the resistance between the terminals of the throttle position sensor.

Standard:

- Reconnect the throttle position sensor connector.

2 Check harness and connector(throttle position sensor – ecm)

- Disconnect the e3 ecm connector.

- measure the resistance between the terminals of the e3 ecm connector.

Standard:

- Check the resistance between the terminals of the e3 ecm connector.

Standard (check for short):

- Reconnect the ecm connector.

Other materials:

Mass or volume air flow circuit

Dtc p0100 mass or volume air flow circuit

Dtc p0102 mass or volume air flow circuit

low input

Dtc p0103 mass or volume air flow circuit

high input

Circuit description

The maf (mass air flow) sensor measures the amount of air flowing through the

throttle valve. The ecm

uses this information ...

Basic repair hint

(A) hints on operations

1

Looks

Always wear a clean uniform.

Hat and safety shoes must be worn.

2

Vehicle protection

Set a grill cover, fender cover, seat cover and floor mat before

starting the operation.

3

Safe ...

Cruise control

The vehicle can be driven at

a set speed even if the

accelerator pedal is not

depressed.

Use the cruise control only

on highways and expressways.

WARNING

■For safe use

Driving safely is solely the

responsibility of the driver.

Therefore, do not overly rely on

this system. The driver is solel ...