Toyota Corolla (E210) 2019-2026 Owners Manual / When trouble arises / Essential information / If your vehicle has to be stopped

in an emergency

Toyota Corolla (E210): If your vehicle has to be stopped in an emergency

Only in an emergency, such as if it becomes impossible to stop the vehicle in the normal way, stop the vehicle using the following procedure:

Stopping the vehicle

1. Steadily step on the brake pedal with both feet and firmly depress it.

Do not pump the brake pedal repeatedly as this will increase the effort required to slow the vehicle.

2. Shift the shift lever to N.

If the shift lever is shifted to N

3. After slowing down, stop the vehicle in a safe place by the road.

4. Stop the engine.

If the shift lever cannot be shifted to N

3. Keep depressing the brake pedal with both feet to reduce vehicle speed as much as possible.

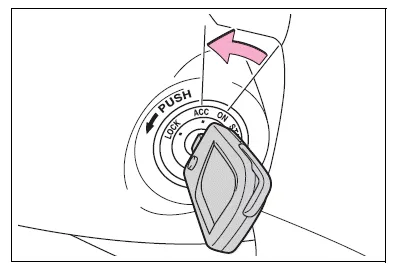

4. Vehicles without a smart key system: Stop the engine by turning the engine switch to ACC.

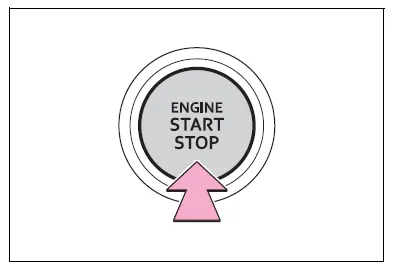

4. Vehicles with a smart key system: To stop the engine, press and hold the engine switch for 2 consecutive seconds or more, or press it briefly 3 times or more in succession.

5. Stop the vehicle in a safe place by the road.

WARNING

■If the engine has to be turned off while driving

- Power assist for the brakes and steering wheel will be lost, making the brake pedal harder to depress and the steering wheel heavier to turn. Decelerate as much as possible before turning off the engine.

- Vehicles without a smart key system: Never attempt to remove the key, as doing so will lock the steering wheel.

Other materials:

Brake fluid

■ Checking fluid level

The brake fluid level should be between the “MAX” and “MIN” lines on the tank.

■ Adding fluid

Make sure to check the fluid type and prepare the necessary item.

1 Slide and lift up the rubber strip to partially remove it as shown.

2 Disconnect the ...

Replacement

1. Work for preventing gasoline from spilling out

2. Remove engine under cover rh

3. Drain coolant

4. Remove front wheel rh

5. Remove cylinder head cover no.2

Remove the 2 nuts, 2 clips and cylinder head cover.

6. Remove air cleaner hose no.1

loosen the 2 air cleaner hose ...

How to use this manual

1. Body panel replacement in this manual

2. Symbols

3. Illustration of weld point symbols

...