Toyota Corolla (E120) 2002–2008 Repair Manual / Engine control system / Ecm (1zz–fe)

Toyota Corolla (E120): Ecm (1zz–fe)

Replacement

1. Disconnect battery negative terminal

2. Remove glove compartment door assy

3. Remove ecm

- Remove the 2 clips using a clip remover. Then, open the cover.

- Disconnect the 4 ecm connectors.

- remove the wire harness from the wire harness clamp.

- Remove the 2 bolts.

- unfasten the claw and clip, then remove the ecm.

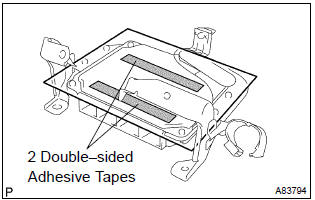

4. Remove ecm cover

- Take the 2 double–sided adhesive tapes off the ecm, then remove the ecm cover.

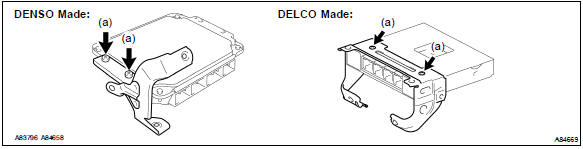

5. Remove ecm bracket no.2 (Denso made)

- Remove the 2 screws, then remove the ecm bracket no.

2.

6. Remove ecm bracket no.1

- Remove the 2 screws, then remove the ecm bracket no.

7. Remove ecm bracket no.3 (Delco made)

- Remove the 2 screws, then remove the ecm bracket no.

8. Install ecm bracket no.3 (Delco made) torque: 3.2 Nvm (33 kgfvcm, 28 in.Vlbf)

9. Install ecm bracket no.1 Torque: 3.2 Nvm (33 kgfvcm, 28 in.Vlbf)

10. Install ecm bracket no.2 (Denso made) torque: 3.2 Nvm (33 kgfvcm, 28 in.Vlbf)

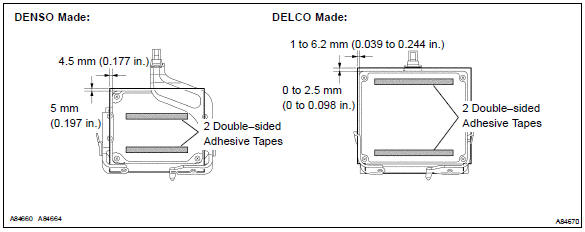

11. Install ecm cover

- Install a new ecm cover to the ecm as shown in the illustration.

12. Install ecm torque: 3.0 Nvm (31 kgfvcm, 27 in.Vlbf)

13. Install glove compartment door assy

14. Connect battery negative terminal torque: 5.4 Nvm (55 kgfvcm, 48 in.Vlbf)

15. Reset memory (a/t transaxle)

Caution

: perform the reset memory (at initialization) when replacing the ecm, engine assembly or automatic transaxle assembly.

- The hand–held tester only.

- Connect the hand–held tester to the dlc3.

- Turn the ignition switch on.

- Perform the reset memory procedure from the engine menu.

Caution

: after performing the reset memory, be sure to perform the road test as described earlier.

Other materials:

Displaying the device status

Select “Bluetooth* info” using .

● Displaying the device name

Select “Device Name” using .

● Displaying the device address

Select “Device Address” using .

*: Bluetooth is a registered trademark of Bluetooth SIG, Inc. ...

Malfunction in water temperature receiver gauge

Wiring diagram

Inspection procedure

1 Read value of hand–held tester

Check output value of ecm.

Connect the hand–held tester to dlc3.

Turn the ignition switch to on and push the hand–held tester main

switch on.

Select the data list mode on the hand–he ...

Rear view monitor system precautions

■ Area displayed on screen

The rear view monitor system displays an image of the view from the bumper of

the rear area of the vehicle.

To adjust the image on the rear view monitor system screen.

• The area displayed on the screen may vary according to vehicle orientation

conditions.

...