Toyota Corolla (E120) 2002–2008 Repair Manual / Engine control system / Throttle body assy

Toyota Corolla (E120): Throttle body assy

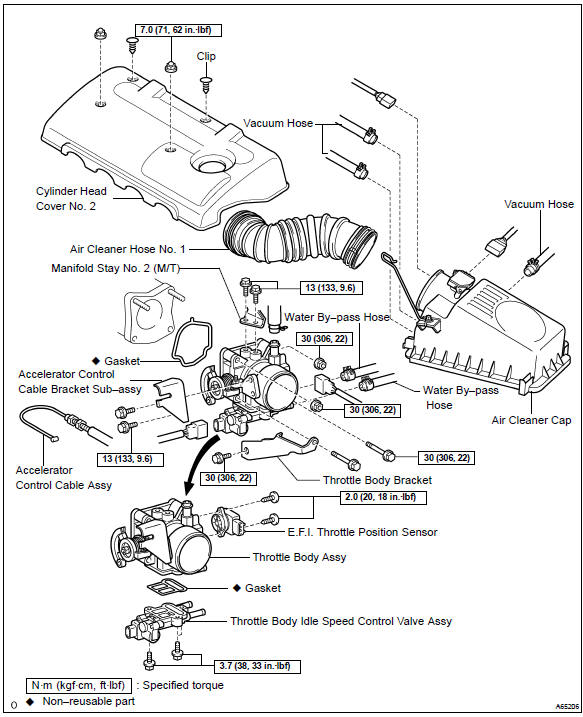

Components

Removal & installation and disassembly & reassembly

1. Drain coolant

2. Remove cylinder head cover no.2

- Remove 2 nuts, 2clips and the cylinder head cover no. 2.

3. Remove air cleaner cap sub–assy

- Disconnect the maf connector.

- disconnect the vsv connector.

- disconnect 3 vacuum hoses, as shown in the illustration.

- loosen an air cleaner hose clump and disconnect an air cleaner hose no. 1.

- remove the air cleaner cap.

4. Remove air cleaner hose no.1

5. Separate accelerator control cable assy

6. Remove throttle body assy

- Disconnect an throttle position sensor connector.

- disconnect a throttle body isc valve assy connector.

- disconnect a pcv hose.

- Disconnect 2 water by–pass hoses.

- Remove 5 bolts, 2 nuts, throttle body bracket and throttle body. (Transaxle m/t)

- Remove 3bolts, 2nuts and throttle body. (Transaxle a/t)

- Remove 2 bolts and accelerator cable bracket.

7. Remove E.F.I. Throttle position sensor

- Remove 2 screws and the throttle position sensor as shown in the illustration.

8. Remove thlottle body idle speed controlvalve assy

- Remove 3 screws and the idle speed control valve assy.

- remove the gasket from the throttle body.

9. Install thlottle body idle speed control valve assy

- Install a new gasket on the throttle body.

- install the idle speed control valve assy with 3 screws.

Torque: 3.7 Nvm (38 kgf·cm, 33 in.Vlbf)

10. Install E.F.I. Throttle position sensor

- Check that the throttle valve is fully close.

- insert the throttle position sensor to the throttle body with it turned counterclockwise by 30 to 90 against the fully close valve position.

- by turning the throttle position sensor clockwise, tighten

2 screws.

Torque: 2.0 Nvm (20 kgf·cm, 18 in.Vlbf)

11. Install throttle body assy

- Install the accelerator control bracket with 2 bolts.

Torque: 13 nvm (133 kgf·cm, 9.6 Ftvlbf)

- Install a new gasket on the intake manifold, as shown in the illustration.

- Install the throttle body with 5 bolts and 2 nuts.(Transaxle

m/t)

torque:

a 30 nvm (306 kgf·cm, 22 ftvlbf) b 13 nvm (133 kgf·cm, 9.6 Ftvlbf)

- Install the throttle body with 3 bolts and 2 nuts.(Transaxle a/t) torque: 30 nvm (306 kgf·cm, 22 ftvlbf)

- Connect 2 water by–pass hoses to the throttle body.

- Connect the pcv hose to the throttle body.

- connect the throttle body idle speed control valve assy connector to the throttle body.

- connect the throttle position sensor connector to the throttle body.

12. Install air cleaner cap sub–assy

- Install the air cleaner cap.

- connect the air cleaner hose.

- Connect 3 vacuum hoses, as shown in the illustration.

- connect the vsv connector.

- connect the intake air flow meter connector.

13. Install cylinder head cover no.2

- Install the cylinder head cover no. 2 With 2 nuts and 2

clips.

Torque: 7.0 Nvm (71 kgf·cm, 62 in.Vlbf)

14. Add coolant

15. Check engine coolant leak

Other materials:

Menu list of the Bluetooth® audio/phone

To enter a menu, press and navigate

menus by using :

*: Bluetooth is a registered trademark of Bluetooth SIG, Inc.

■Bluetooth® audio/phone system functions

Depending on the Bluetooth® device, certain functions may not be available. ...

Inspection procedure

1 Check side squib(rh) circuit(airbag sensor assy center – front

seat airbag assy rh)

Disconnect the negative (–) terminal cable from the battery,

and wait at least for 90 seconds.

disconnect the connectors between the airbag sensor

assy center and the front seat airbag assy ...

Diagnostic trouble code chart

The inspection procedures are shown in the table below. This table allows

efficient and accurate troubleshooting

using the diagnostic trouble codes displayed in the diagnostic trouble code

chart. Proceed with

troubleshooting in accordance with the inspection procedures listed in the

diagnost ...