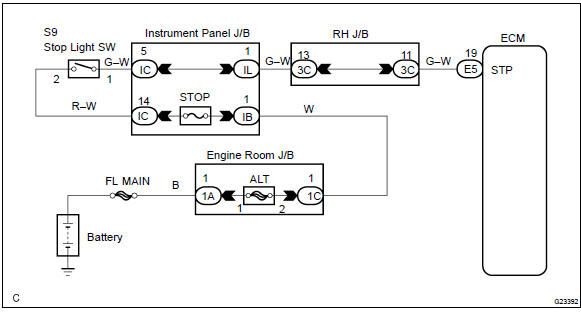

Toyota Corolla (E120): Circuit description

The purpose of this circuit is to prevent the engine from stalling while driving in lock–up condition, when brakes are suddenly applied.

When the brake pedal is depressed, this switch sends a signals to the ecm. Then the ecm cancels the operation of the lock–up clutch while braking is in progress.

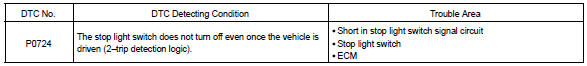

Monitor description

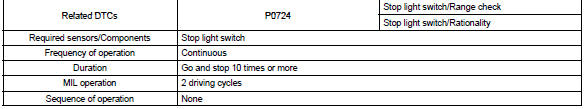

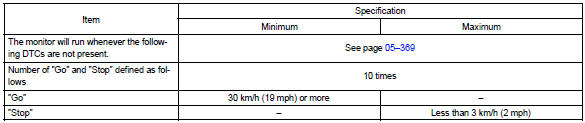

The circuit prevents the engine from stopping when the vehicle is stopped by sudden braking when the torque converter clutch is in the ”lock–up” mode. The ecm receives the signal from the stop light switch at the time brake pedal is depressed. Then, the ecm sends the signal to the lock–up solenoid valve not to be in lock–up condition. When the stop light switch remains on during ”stop and go” driving, the ecm interprets this as a fault in the stop light switch and the mil comes on. The vehicle must stop and go (3 km/h (2 mph) to 30 km/h (19 mph)) ten times for two driving cycles in order to detect malfunction.

Monitor strategy

Typical enabling condition

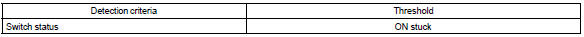

Typical malfunction thresholds

Wiring diagram

Other materials:

Registering and connecting from the “Bluetooth* Setup” screen

To display the screen shown below, press the “SETUP” button and select “Bluetooth*”

on the “Setup” screen.

1 Select to connect the device to be used with multimedia system.

2 Select to register a Bluetooth® device to be used with multimedia system.

3 Select to set detailed Bluet ...

Inspection

1. Inspect front seat inner belt assy lh

When fastening the seat belt (buckle switch on).

Inspect the continuity and resistance between the

terminals.

Standard:

If the result is not as specified, replace the inner belt.

When releasing the seat belt (buckle switch ...

Floor shift parking lock cable assy (atm)

Replacement

1. Precaution

2. Disconnect battery negative terminal

3. Place front wheels facing straight ahead

4. Remove horn button assy

5. Remove steering wheel assy

sst 09950–50013 (09951–05010, 09952–05010, 09953–05020, 09954–05021)

6. Remove steering column cover

7. Remove c ...