Toyota Corolla (E120): Replacement

1. Remove engine under cover rh

2. Drain coolant

3. Remove front wheel rh

4. Remove cylinder head cover no.2

- Remove the 2 nuts, 2 clips and cylinder head cover.

5. Remove fan and generator v belt

- Turn the v–ribbed belt tensioner slowly clockwise and loosen it. Then, remove the fan and generator v belt and put back the v–ribbed belt tensioner little by little and fix it quietly.

6. Separate vane pump assy

Ntice:

do not disconnect the hose.

7. Remove generator assy

8. Remove engine mounting insulator sub–assy rh

- Remove the ps oil pump reservoir and put it aside.

- place a wooden block between the jack and engine, and set the jack, then remove the 4 bolts, the 2 nuts and engine mounting insulator rh.

9. Disconnect engine wire

- Remove the 5 clamps from the 5 clamp brackets.

- disconnect the 4 ignition coil connectors.

- Remove the bolt and nut installing the engine wire.

10. Remove ignition coil assy

- Remove the 4 bolts and 4 ignition coils.

11. Disconnect ventilation hose

- Disconnect the ventilation hose from the cylinder head cover.

12. Disconnect ventilation hose no.2

- Disconnect the ventilation hose from the cylinder head cover.

13. Remove cylinder head cover sub–assy

- Remove the 9 bolts, 2 seal washers, 2 nuts, 3 clamp brackets and cylinder head cover.

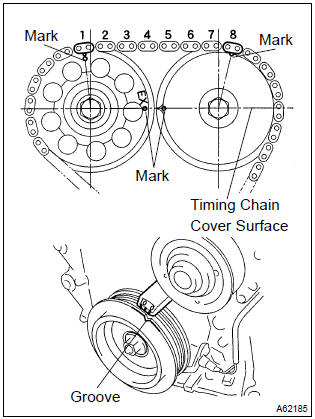

14. Set no. 1 Cylinder to tdc/compression

- Turn the crankshaft pulley, and align its groove with timing mark ”0” of the timing chain cover.

- check that the point marks of the camshaft timing sprocket and vvt timing sprocket are in straight line on the timing chain cover surface as shown in the illustration.

Hint

: if not, turn the crankshaft 1 revolution (360 ) and align the marks as above.

15. Remove crankshaft pulley

- Using sst, remove the pulley bolt.

Sst 09960–10010 (09962–01000, 09963–01000)

- remove the crankshaft pulley from the crankshaft.

16. Remove v–ribbed belt tensioner assy

- Remove the bolt, nut and v–ribbed belt tensioner.

Hint

: handle a jack up and down to remove the bolt.

17. Remove water pump assy

18. Remove transverse engine engine mounting bracket

- Remove the 3 bolts and transverse engine engine mounting bracket

19. Remove crank position sensor

- Remove the 2 bolts installing the crank position sensor.

20. Remove chain tensioner assy no.1

- Remove the 2 nuts and chain tensioner.

Notice

: be sure not to revolve the crankshaft without the chain tensioner.

21. Remove timing chain or belt cover sub–assy

- Remove the 11 bolts and nuts.

- using a torx wrench socket (e8), remove the stud bolt.

- remove the timing chain cover by prying the portions between the cylinder head and cylinder block with a screwdriver.

Notice

: be careful no tot damage the contact surfaces of the timing chain cover, cylinder head and cylinder block.

22. Remove timing gear cover oil seal

- Using a screwdriver, remove the oil seal.

23. Remove crankshaft position sensor plate no.1

24. Remove chain tensioner slipper

- remove the bolt and chain tensioner slipper.

25. Remove chain sub–assy

- Remove the timing chain with the crankshaft timing gear plying screwdrivers as shown in the illustration.

Notice

:

- put shop rag to protect the engine.

- In case of revolving the camshafts with the chain off the sprockets, turn the crankshaft 1/4 revolution for valves not to touch the pistons.

26. Install chain sub–assy

- Set no. 1 Cylinder to tdc/compression.

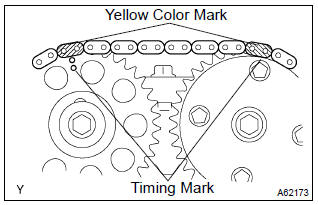

- Turn the hexagonal wrench head portion of the camshafts, and align the point marks of the camshaft timing sprockets.

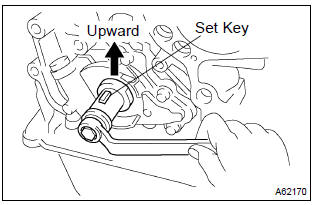

- Using a crankshaft pulley bolt, turn the crankshaft and set the set key on the crankshaft upward.

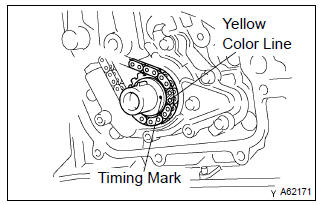

- Install the timing chain on the crankshaft timing sprocket with the yellow color link aligned with the timing mark on the crankshaft timing sprocket.

Hint

: three yellow color links are on the chain.

- Using sst, install the crankshaft timing sprocket.

Sst 09223–22010

- Install the timing chain on the camshaft timing sprockets with the yellow color links aligned with the timing marks on the camshaft timing sprockets.

27. Install chain tensioner slipper

- install the chain tensioner slipper with the bolt.

Torque: 19 nvm (194 Kgf·cm, 14 ft·lbf)

28. Install crankshaft position sensor plate no.1

- Install the plate with the ”f” mark facing forward.

29. Install timing gear cover oil seal

- Apply mp grease to a new oil seal lip.

- using sst, tap in the oil seal until its surface is flush with

the timing chain cover edge.

Sst 09223–22010

N

otice

: keep the lip off foreign materials.

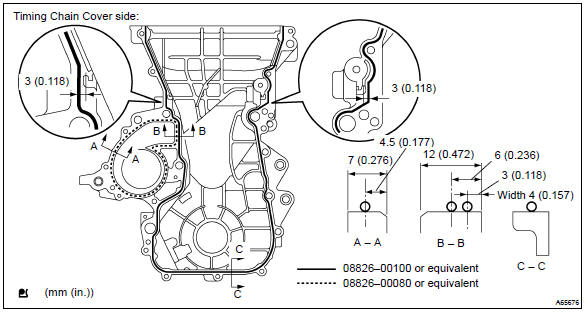

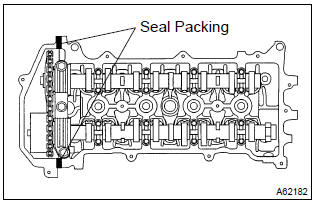

30. Install timing chain or belt cover sub–assy

- Remove any old packing material from the contact surface.

- apply seal packing in the shape of bead (diameter 3.5

Mm – 4.5 Mm (0.1379 – 0.177 In.)) Consequently as

shown in the illustration.

Seal packing: water pump part part no. 08826–00100 Or equivalent other part part no. 08826–00080 Or equivalent.

Notice

:

- remove any oil from the contact surface.

- Install the oil pan within 3 minutes after applying seal packing.

- Do not put into engine oil within 2 hours after installing.

- Install the timing chain cover with the 11 bolts and nut.

Torque:

a: 13 nvm (133 Kgf·cm, 10 ft·lbf) b: 19 nvm (194 Kgf·cm, 14 ft·lbf) - using a torx wrench socket (e8), install the stud bolt.

Torque: 9.5 Nvm (97 Kgf·cm, 84 in.Vlbf)

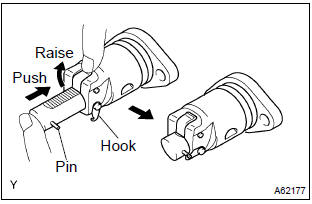

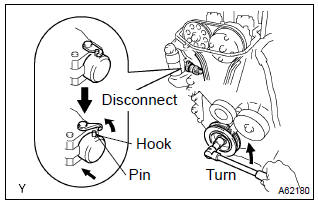

31. Install chain tensioner assy no.1

- Check the o–ring is clean, and set the hook as shown in the illustration.

- Apply engine oil to the chain tensioner and install it withe

2 nuts.

Torque: 9.0 Nvm (92 Kgf·cm, 80 in.Vlbf)

N

otice

: when installing the tensioner, set the hook again if the hook release the plunger.

32. Install crank position sensor

- Install the crank position sensor with the 2 bolts.

Torque: 9.0 Nvm (92 Kgf·cm, 80 in.Vlbf)

33. Install transverse engine engine mounting bracket

- Install the transverse engine engine mounting bracket

with the 3 bolts.

Torque: 47 nvm (479 Kgf·cm, 35 ft·lbf)

34. Install water pump assy

35. Install v–ribbed belt tensioner assy

- Install the v–ribbed belt tensioner with the nut and bolt.

Torque:

nut 29 nvm (296 Kgf·cm, 21 ft·lbf) bolt 69 nvm (704 Kgf·cm, 51 ft·lbf)

36. Install crankshaft pulley

- Align the pulley set key with the key groove of the pulley, and slide on the pulley.

- using sst, install the crankshaft pulley bolt.

Sst 09960–10010 (09962–01000, 09963–01000) torque: 138 nvm (1,407 Kgf·cm, 102 ft·lbf)

- Turn the crankshaft counter clockwise, and disconnect the plunger knock pin form the hook.

- Turn the crankshaft clockwise, and check that the slipper is pushed by the plunger.

Hint

: if the plunger does not spring out, press the slipper into the chain tensioner with a screwdriver so that the hook is released from the knock pin and the plunger springs out.

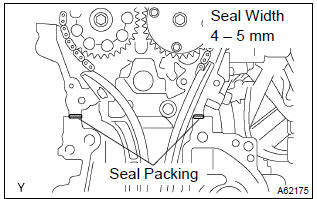

37. Install cylinder head cover sub–assy

- Remove any old pacing (fipg) material.

- apply seal packing to 2 locations as shown in the illustration.

Seal packing: part no. 08826–00080 Or equivalent

N

otice

:

- remove any oil from the contact surface.

- Install the cylinder head cover within 3 minutes after applying seal packing.

- Do not put into engine oil 2 hours after installing.

- Install the cylinder head cover and 3 cable brackets with

the 9 bolts, 2 seal washers and 2 nuts. Uniformly tighten

the bolts and nuts, in the several passes.

Torque:

a 11 nvm (112 Kgf·cm, 8 ft·lbf) b 9.0 Nvm (92 Kgf·cm, 80 in.Vlbf)

38. Install ignition coil assy

- Install the 4 ignition coils with the 4 bolts.

Torque: 9.0 Nvm (92 Kgf·cm, 80 in.Vlbf)

39. Install engine wire

- Install the engine wire with the bolt and nut.

Torque: 9.0 Nvm (92 Kgf·cm, 80 in.Vlbf)

40. Install engine mounting insulator sub–assy rh

- Install the engine mounting insulator with the 4 bolts and

2 nuts.

Torque: 52 nvm (530 Kgf·cm, 38 ft·lbf)

41. Install generator assy

42. Install vane pump assy

43. Install cylinder head cover no.2

- Install the cylinder head cover with the 2 nuts and 2 clips.

Torque: 7.0 Nvm (71 Kgf·cm, 62 in.Vlbf)

44. Install front wheel rh torque: 103 nvm (1,050 Kgf·cm, 76 ft·lbf)

45. Add coolant

46. Check engine coolant leak

47. Check engine oil leak

Other materials:

On–vehicle inspection

1. Inspect speedometer

check the operation.

Using a speedometer tester, inspect the speedometer fro allowable

indication error and check

the operation of the odometer.

Reference:

Notice:

tire wear and tire over or under inflation will increase the indication error.

...

Outer rear view mirror assy lh

Replacement

Hint:

installation is according to the reverse order of the removal.

In the rh side, work in the same procedure as in the lh side.

1. Remove front armrest assy lh

2. Remove power window regulator master switch assy (w/ power window)

3. Remove front armrest base panel upper ...

On–vehicle inspection

1. Inspect pressure switch no.1.

Magnetic clutch control:

inspect pressure switch operation.

Set on the manifold gauge set.

Connect the positive (+) lead from the ohmmeter to

terminal 4 and the negative (–) lead to terminal 1.

Check continuity between termin ...