Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Oxygen sensor circuit slow

response / Circuit description

Toyota Corolla (E120): Circuit description

Refer to dtc p0130

|

Dtc no. |

Dtc detection condition |

Trouble area |

| P0133 | After engine has been warmed up, if response time that heated

oxygen sensor’s output voltage reaches from rich to lean. Or from lean to rich, is 0.6 Second or more during idling. (2 Trip detection logic) |

|

| If response time of heated oxygen sensor’s output voltage in one rich–lean cycle is 6 seconds or more during idling. (2 Trip detection logic) |

Hint

: sensor 1 refers to the sensor closest to the engine assembly.

Monitor description

The engine control module (ecm) uses the heated oxygen sensor information to regulate the air–fuel ratio close to a stoichiometric ratio. This maximizes the catalytic converter’s ability to purify the exhaust gases.

The sensor detects oxygen levels in the exhaust gas and sends this signal to the ecm.

The inner surface of the sensor element is exposed to the outside air. The outer surface of the sensor element is exposed to the exhaust gas. The sensor element is made of the platinum coated zirconia and includes an integrated heating element. The heated oxygen sensor has the characteristic whereby its output voltage change suddenly in the vicinity of the stoichiometric air–fuel ratio. The heated oxygen sensor generates waveform of a voltage between 0 v and 1 v in response to the oxygen concentration in exhaust gas.

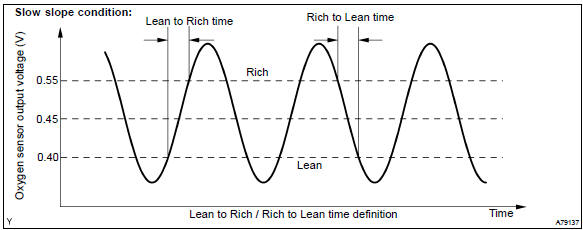

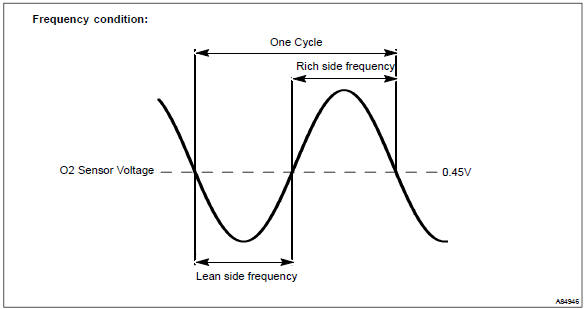

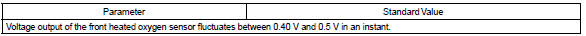

When the output voltage of the heated oxygen sensor is 0.55 V or more, the ecm judges that the air–fuel ratio is rich. When it is 0.40 V or less, the ecm judges that the air–fuel ratio is lean.

The ecm monitors the response feature of the heated oxygen sensor. If the response time of the sensor output status change from rich to lean or vice versa becomes longer, the ecm interprets this as a malfunction in the heated oxygen sensor and sets a dtc.

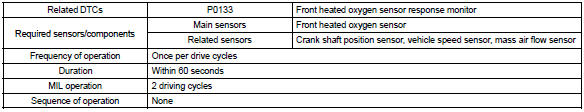

Monitor strategy

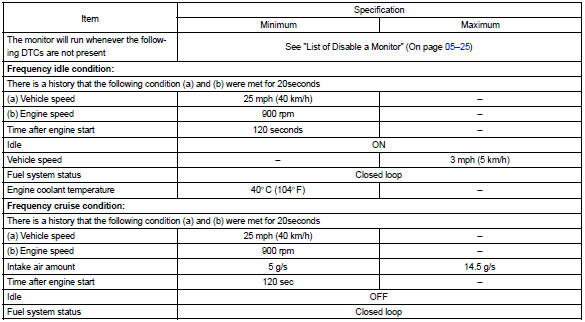

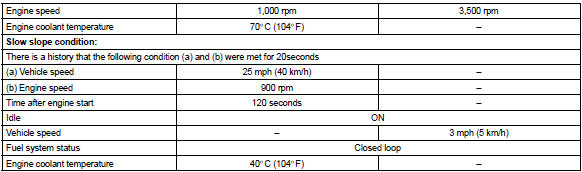

Typical enabling condition

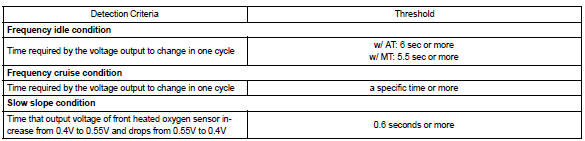

Typical malfunction thresholds

Component operating range

Wiring diagram

Refer to dtc p0130

Other materials:

Replacement

1. Remove radiator grille sub–assy

2. Remove front bumper cover

3. Remove fog lamp assy lh

Remove a nut and release a claw.

remove the fog light assy lh.

4. Put vehicle these conditions

5. Adjust fog light aim

6. Check fog light aim ...

Circuit description

A flat type knock sensor (non–resonant type) has the structure that can

detect the vibration in a wider band

of frequency from about 6 khz to 15 khz and has the following features.

Knock sensors are fitted on the cylinder block to detect the engine knocking.

The sensor contains a piezoele ...

Uniform Tire Quality Grading

This information has been prepared in accordance with regulations issued by the

National Highway Traffic Safety Administration of the U.S. Department of Transportation.

It provides the purchasers and/or prospective purchasers of Toyota vehicles with

information on uniform tire quality grading.

...