Toyota Corolla (E120): Circuit description

Refer to dtc p0115

|

Dtc no. |

Dtc detection condition |

Trouble area |

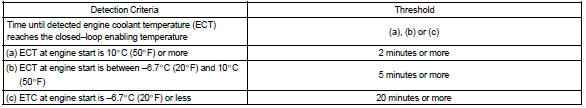

| P0125 | If the engine coolant temperature (ect) was less than –6.6 °C (20 °F) when starting the engine, and 20 minutes after the engine start, the ect sensor still indicates below 20 °C (68 °F) |

|

| If the ect was between –6.6 °C (20 °F) and 10 °C (50 °F) when start, 5 minutes after the start, the ect sensor still indicates below 20 °C (68 °F) | ||

| If the ect was greater than 10 °C (50 °F) when starting the engine, and 2 minutes after the engine start, ect sensor still indicates below 20 °C (68 °F) |

Monitor description

The engine coolant temperature (ect) sensor is used to monitor the temperature of the engine coolant. The resistance of the sensor varies with the actual coolant temperature. The ecm applies a voltage to the sensor and the varying resistance of the sensor causes the signal voltage to vary. The ecm monitors the ect signal voltage after engine start–up. If, after sufficient time has passed, the sensor still reports that the engine is not warm enough for closed–loop fuel control, the ecm interprets this as a fault in the sensor or cooling system.

Example: the engine coolant temperature was 0 c (32 f) at engine start. After 5 minutes running time, the coolant temperature sensor still indicates that the engine is not warm enough to begin air–fuel ratio feedback control.

The ecm interprets this as a fault in the sensor or cooling system and will set a dtc.

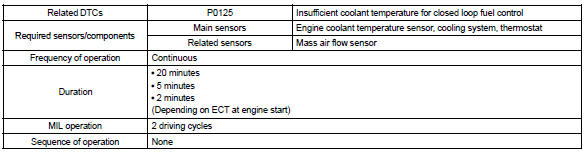

Monitor strategy

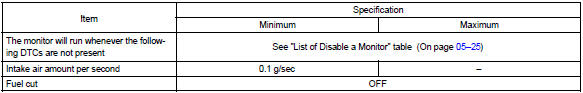

Typical enabling conditions

Typical malfunction thresholds

Wiring diagram

Refer to dtc p0115

Other materials:

Replacing light bulbs

■ Headlight high beams

1 Turn the bulb base counterclockwise.

2 Pull the bulb out while pressing the lock release of the connector.

3 Replace the light bulb, and install the bulb base.

Align the 3 tabs on the light bulb with the mounting and insert.

4 Turn and secure the bulb base.

...

Windshield wiper motor assy

Replacement

1. Remove windshield wiper arm cover

2. Remove fr wiper arm rh

operate the wiper and stop the windshield wiper motor assy at the

automatic stop position.

remove a nut and fr wiper arm rh.

3. Remove fr wiper arm lh

remove a nut and fr wiper arm lh.

4 ...

Manual air conditioning system∗

Air conditioning controls

► Heater

► Air conditioning system

■ Adjusting the temperature setting

► Heater

To adjust the temperature setting, turn the

dial clockwise to increase the temperature.

► Air conditioning system

To adjust the temperature setting, tu ...