Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Oxygen sensor heater control

circuit... / Circuit description

Toyota Corolla (E120): Circuit description

Refer to dtc p0130

Hint

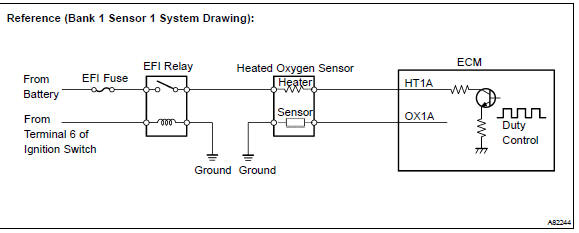

: the ecm provides a pulse width modulated control circuit to adjust current through the heater. The heated oxygen sensor heater circuit uses a relay on the b+ side of the circuit.

Monitor description

The ecm uses the heated oxygen sensor information to regulate the air–fuel ratio close to a stoichiometric ratio. This maximizes the catalytic converter’s ability to purify the exhaust gas. The sensor detects oxygen levels in the exhaust gas and sends this signal to the ecm.

The inner surface of the sensor element is exposed to the outside air. The outer surface of the sensor element is exposed to the exhaust gas. The sensor element is made of the platinum coated zirconia and includes an integrated heating element. The heated oxygen sensor has the characteristic whereby its output voltage change suddenly in the vicinity of the stoichiometric air–fuel ratio. When heated, the sensor becomes very efficient. If the temperature of the exhaust is low, the sensor will not generate useful voltage signals without supplemental heating. The ecm regulates the supplemental heating using a duty–cycle approach to regulate the average current in the heater element. If the heater current is out of the normal range, the sensor’s output signals will be inaccurate and the ecm cannot regulate the air–fuel ratio properly. When the heater current is out of the normal operating range, the ecm interprets this as a malfunction and sets a dtc.

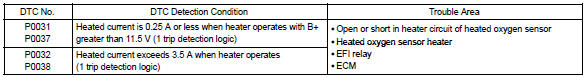

Example: the ecm will set a high current dtc if the current in the sensor is more than 2 a when the heater is off.

Similarly, the ecm will set a low current dtc if the current is less than 0.25 A when the heater is on.

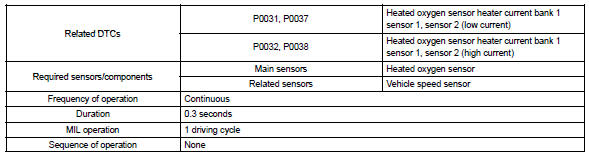

Monitor strategy

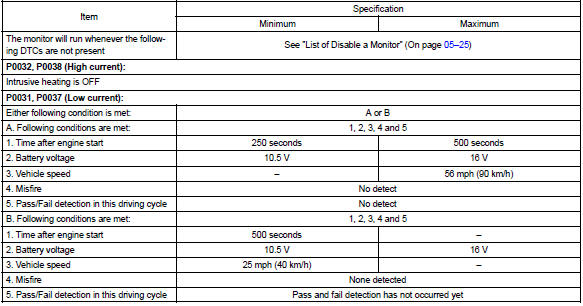

Typical enabling conditions

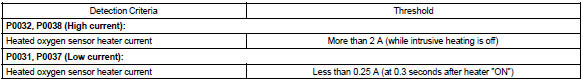

Typical malfunction thresholds

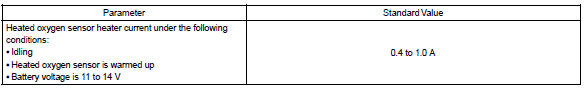

Component operating range

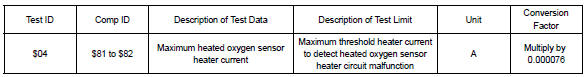

Monitor result (mode 06 data)

Refer to page 05–27 for detailed information on checking monitor status.

Wiring diagram

Refer to dtc p0130

Other materials:

When stopping the engine with the shift lever in a position other than P (vehicles

with a continuously variable transmission)

If the engine is stopped with the shift lever in a position other than P, the

engine switch will not be turned off but instead be turned to ACCESSORY mode. Perform

the following procedure to turn the switch off:

1 Check that the parking brake is set.

2 Shift the shift lever to P.

► Vehi ...

Air outlet layout and operations

■ Location of air outlets

The air outlets and air volume

changes according to the

selected air flow mode.

:If equipped

■ Adjusting the position of

and opening and closing

the air outlets

Front center

Direct air flow to the left or right, up

or down

Front right-hand side

Direct air flow to th ...

Adjustment

1. Inspect and adjust clutch pedal sub–assy

Turn over the floor carpet.

check that the pedal height is correct.

Pedal height from asphalt sheet:

135.8 – 145.8 Mm (5.346 – 5.740 In.)

adjust the pedal height.

Loosen the lock nut and turn the stopper bolt until

...