Toyota Corolla (E120) 2002–2008 Repair Manual / Audio & visual / Antenna cord sub–assy

Toyota Corolla (E120): Antenna cord sub–assy

Replacement

Hint

: components:

1. Remove instrument panel sub–assy upper

Hint

:

- refer to the procedure until the step, ”remove instrument panel sub–assy upper” of instrument panel sub–assy lower.

- Remove the related parts as long as the antenna cord sub–assy can be removed.

2. Remove visor holder

Hint

:

- refer to the procedure until the step, ”remove visor holder” of roof headlining assy.

- Remove the parts related to the roof headlining assy in the range that antenna cord can be cut off.

3. Remove sun roof opening trim moulding (w/ sliding roof)

4. Disconnect antenna cord sub–assy

- Rear side: disconnect the connector and antenna cord plug.

- rear side: remove the 2 clamps.

- Front side: remove the 9 clamps.

5. Remove roof headlining assy

Notice

: do not bend the roof headlining assy.

6. Remove antenna cord sub–assy

- remove the antenna cord sub–assy from the roof headlining.

7. Install antenna cord sub–assy

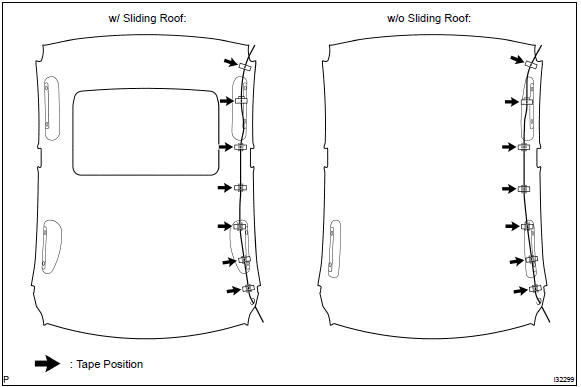

- tape the antenna cord sub–assy at the position of the roof headlining shown in the illustration.

Notice

:

- the antenna cord sub–assy should come to the center of the tape (100 mm(3.94 In.) X 25 mm(0.98 In.)) When taped.

- Try not to touch the adhesive side of the tape when taping.

- Install the roof headlining assy .

- engage the 9 clamps at the front side of antenna cord.

- connect the plug and connector at the rear side of antenna cord.

8. Install rear seat back assy (fixed type rear seat)

9. Install rear seat back assy (separated type rear seat)

10. Install bench type rear seat cushion assy( or 72–8)

11. Install instrument panel sub–assy upper

Hint

: refer to the procedure until the step, ”install instrument panel sub–assy upper” of instrument panel sub–assy lower.

Other materials:

Inspection procedure

1 Inspect stop lamp switch assy

Check that the stop light lights up when brake pedal is depressed and

turns off when the brake pedal

is released.

2 Inspect skid control ecu terminal voltage(stp terminal)

Disconnect skid control ecu connector.

measure voltage between termina ...

Ecm (1zz–fe)

Replacement

1. Disconnect battery negative terminal

2. Remove glove compartment door assy

3. Remove ecm

Remove the 2 clips using a clip remover. Then, open the

cover.

Disconnect the 4 ecm connectors.

remove the wire harness from the wire harness clamp.

Remove the 2 ...

Body rocker panel moulding lh

Replacement

Hint:

use the same procedures for the rh side and lh side.

1. Remove body rocker panel moulding lh

Remove the 8 retainers.

using a screwdriver, remove the moulding.

Hint:

tape the screwdriver tip before use.

remove the 7 clips from the moulding.

2. Insta ...