Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Evaporative emission control

system leak detected / Circuit description

Toyota Corolla (E120): Circuit description

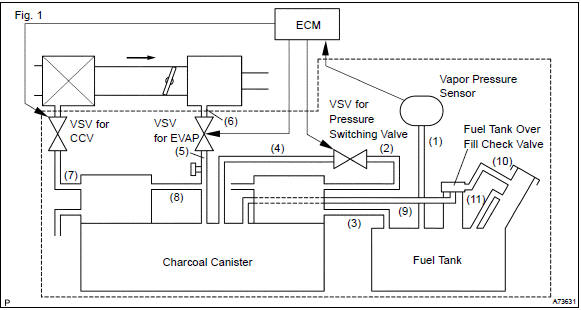

The vapor pressure sensor and the vsv for the canister closed valve (ccv) are used to detect abnormalities in the evaporative emission control system. The ecm decides whether there is an abnormality in the evaporative emission control system based on the vapor pressure sensor signal.

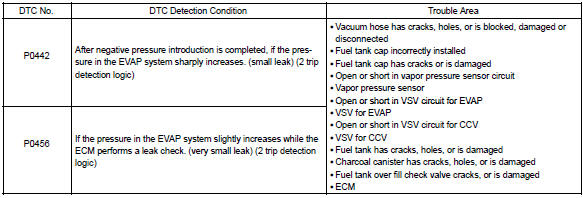

Dtc p0442 or p0456 is recorded by the ecm when evaporative emissions leak from the components within the dotted line in fig. 1 Below, or when the vapor pressure sensor malfunctions.

Hint

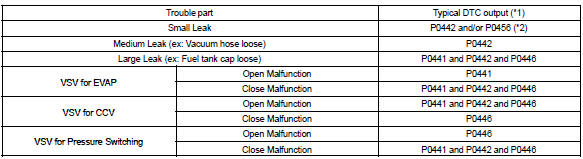

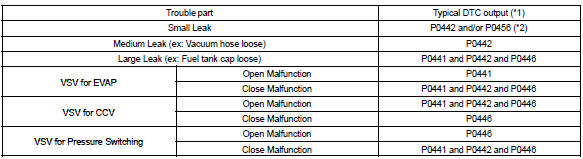

: typical dtc output of each trouble part.

*1: Ecm may output some other dtcs combination.

*2: Refer to dtc p0441 and p0446

Monitor description

The evaporative emission system consists of the vapor pressure sensor, the canister close valve (ccv), the vsv for pressure switching valve and the vsv for evap (purge vsv), those are used to detect malfunction in the system by ecm.

This test will run once per driving cycle when the ecm detects stable vapor pressure in the fuel tank. While the vehicle is being driven on rough or winding roads, the movement of the fuel in the tank will cause unstable fuel tank vapor pressures and the diagnostic test will not executed.

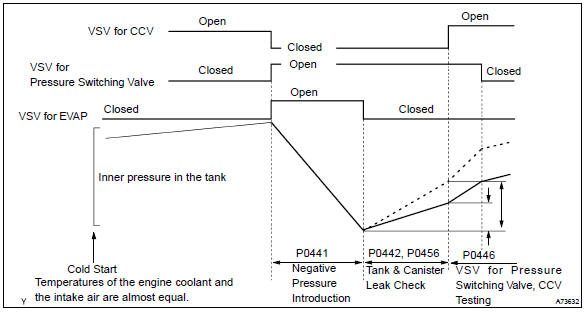

The ecm performs the following steps:

- the ccv is closed. (Shutting the system)

- the fuel tank pressure stability is checked. The diagnostic is disabled if the pressure change is more than specified value.

- the vsv for evap is opened. This introduces a negative pressure from the intake manifold to the fuel tank.

- the vsv for evap is closed and the negative pressure is sealed in the fuel tank.

- the ecm monitors the increase in fuel tank pressure for:

- rapid increase in the internal pressure i.E. A large leak: 0.040 Or more

- pressure rise just above normal

If the ecm detects either of above conditions, it will interpret this as a leak in the evap system. The ecm will illuminate the mil (2–trip detection logic) and set a dtc.

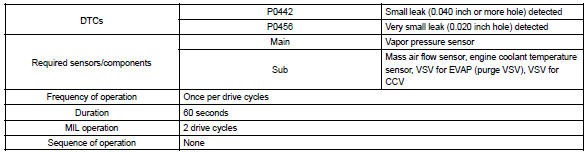

Monitor strategy

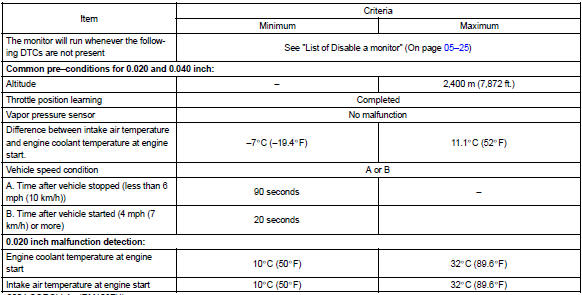

Typical enabling conditions

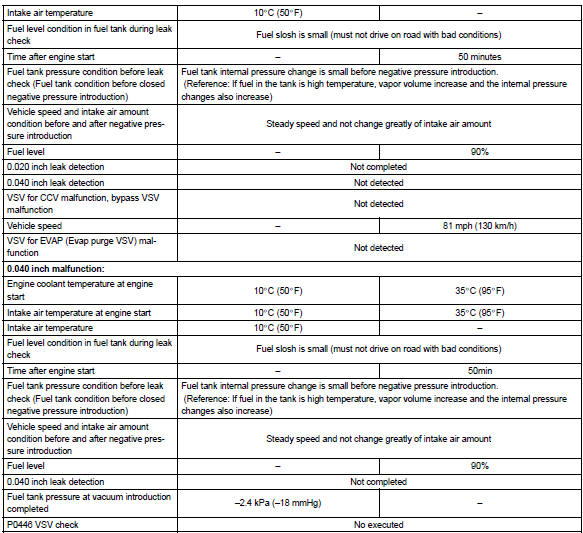

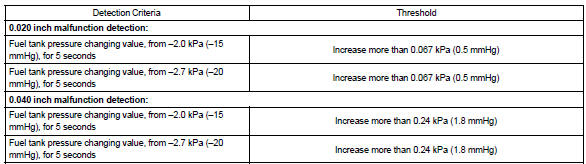

Typical malfunction thresholds

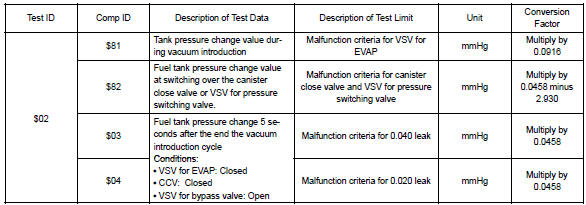

Monitor result (mode 06 data)

Refer for detailed information on checking monitor status.

Other materials:

Dialing by selecting a name

1 Select “Phonebook” using .

2 Select the desired name using

and press the off-hook switch.

By pressing (Add S. Dial) and then

one of the speed dial buttons (from

to ) while the desired name is selected,

it can be registered as a speed dial. ...

Adjustment

1. Headlight aim only

place the vehicle in the following conditions.

The area around the headlight is not deformed.

The vehicle is parked on a level surface.

Tire inflation pressure is in the specified value .

A driver is in the driver’s seat and the vehicle is in a state rea ...

Trip information

■ Switching the display

Items displayed can be switched by pressing the “DISP” switch.

■ Odometer

Displays the total distance the vehicle has been driven.

Except vehicles with a manual transmission: Press and hold the “DISP” switch

to change the display to the Eco Driving ...