Toyota Corolla (E120): Adjustment

1. Headlight aim only

- place the vehicle in the following conditions.

- The area around the headlight is not deformed.

- The vehicle is parked on a level surface.

- Tire inflation pressure is in the specified value .

- A driver is in the driver’s seat and the vehicle is in a state ready for driving (with a tank full).

- The vehicle has been bounced several times.

- check the headlight aiming.

- Prepare a thick white paper.

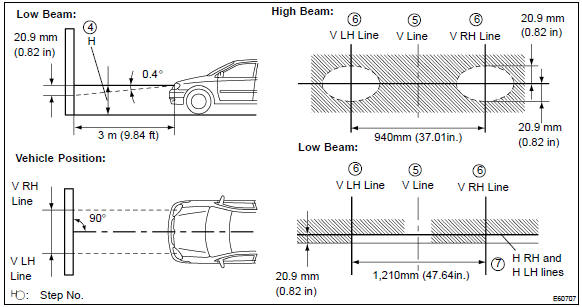

- Stand the paper perpendicular to the ground at the position 9.84 Ft away from the headlights.

- Ensure that the center line of the vehicle and the paper face forms a 90–degree angle as shown in the illustration.

- Draw a horizontal line (h line) on the paper, showing where the headlights should strike.

- Draw a vertical line (v line) to where the center line of the vehicle is to be.

- Draw 2 vertical lines to where the both headlights should strike (v rh and v lh lines).

- Draw a horizontal line (by connecting the both low beam center marks) to where the headlights should strike (h rh and h lh lines).

- Take appropriate measures to prevent any influence of other lights.

- Set the headlights leveling position to ”0” position and adjust the angle of the headlight axis.

Hint

: the h rh and h lh line is 0.4° Below the horizontal line (h line) of the light axis.

- Start the engine.

- Turn the headlights on.

- Check that the headlights properly strike the position shown in the illustration.

- If not, adjust the lights in the vertical direction.

Hint

:

- as shown in the illustration, adjust each aim of the rh and lh lights.

- When adjusting the headlight aim in the veatical direction: using adjusting bolt, adjust the headlight aim to be within the specified range.

Hint

: the optical aim moves upward when turning a screwdriver clockwise, while it moves downward when turning a screwdriver counterclockwise.

Other materials:

Replacement

Hint: components:

1. Precaution

2. Disconnect battery negative terminal

3. Remove horn button assy

Place the front wheels facing straight ahead.

using a torx socket wrench (t30), loosen the 2 torx

screws until the groove along the screw circumference

catches on the screw ca ...

If the vehicle becomes stuck

Carry out the following procedures if the tires spin or the vehicle becomes

stuck in mud, dirt or snow:

1 Stop the engine. Set the parking brake and shift the shift lever to P (automatic

transmission or continuously variable transmission) or N (manual transmission).

2 Remove the mud, snow or s ...

On–vehicle inspection

1. Washer motor

Operation check

pour the water into the washer jar with the washer

motor and the pump installed to the washer jar assy.

Connect the battery (+) to terminal 2 of the washer

motor and the pump, the battery (–) to terminal 1 of

the washer motor and the pump ...