Toyota Corolla (E120) 2002–2008 Repair Manual / Automatic transmission / trans / Transmission valve body assy (atm)

Toyota Corolla (E120): Transmission valve body assy (atm)

Replacement

1. Remove engine under cover lh

2. Drain automatic transaxle fluid

- remove the drain plug, gasket and drain atf.

- install a new gasket and drain plug.

Torque: 17.5 Nvm (178 Kgf·cm, 13 ft·lbf)

3. Remove automatic transaxle oil pan sub–assy

- Remove the 18 bolts, oil pan and gasket.

Notice

: some fluid will remain in the oil pan. Remove all pan bolts, and carefully remove the oil pan assembly. Discard the gasket.

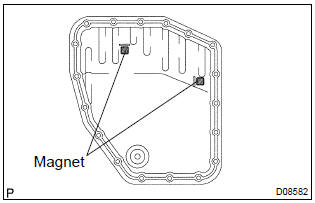

- remove the 2 magnets from oil pan.

- Examine particles in pan.

- Remove the magnets and use them to collect any

steel chips. Look carefully at the chips and particles

in the pan and the magnet to anticipate what type

of wear you will find in the transaxle.

Steel (magnetic): bearing, gear and plate wear brass (non–magnetic): bearing wear

4. Remove valve body oil strainer assy

- Remove the 3 bolts and oil strainer.

Notice

: be careful as some fluid will come out with the oil strainer.

5. Remove transmission valve body assy

- Disconnect the 4 solenoid connecters.

- Remove the bolt and manual detent spring.

- Remove the 17 bolts.

- While disconnecting the manual valve connecting rod from the manual valve lever, remove the valve body with the manual valve together.

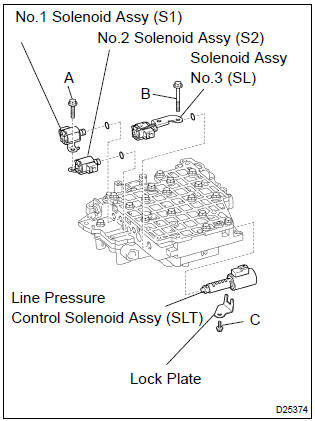

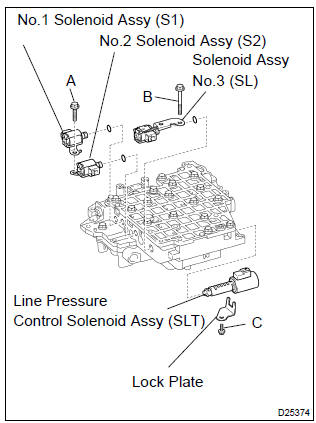

- Remove the 2 bolts and 3 solenoid valves.

- remove the 3 o–rings from each of the solenoid valves.

- remove the bolt, lock plate and line pressure control valve.

6. Install transmission valve body assy

- Coat 3 new o–rings with atf and install them to each solenoid valves.

- install the no.1 And no.2 Solenoid valves with the bolt.

- install the no.3 Solenoid valve with the bolt.

- install the line pressure control solenoid valve and lock

plate with the bolt.

Torque:

bolt a: 11 n·m (110 kgf·cm, 8 ft·lbf) bolt b: 11 n·m (110 kgf·cm, 8 ft·lbf) bolt c: 6.5 N·m (66 kgf·cm, 58 in.Vlbf) bolt length:

bolt a: 25 mm (0.984 In.) Bolt b: 60 mm (2.362 In.) Bolt c: 12 mm (0.472 In.)

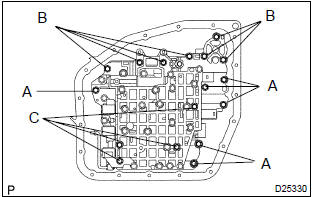

- While connecting the manual valve connecting rod to the manual valve lever, install the valve body with the manual valve together.

- Install the 17 bolts.

Bolt length:

bolt a: 20 mm (0.79 In.) Bolt b: 28 mm (1.10 In.) Bolt c: 50 mm (1.97 In.) Torque: 10 n·m (100 kgf·cm, 7 ft·lbf)

- Install the manual detent spring and bolt.

Torque: 10 n·m (100 kgf·cm, 7 ft·lbf)

- Connect the 4 solenoid connectors.

7. Install valve body oil strainer assy

- Install the oil strainer with the 3 bolts.

Bolt length:

a bolt: 12 mm (0.47 In.) B bolt: 20 mm (0.79 In.) Torque: 10 n·m (100 kgf·cm, 7 ft·lbf)

8. Install automatic transaxle oil pan sub–assy

- Install the 2 magnets to the oil pan.

- Install a new gasket to the oil pan and install them to the transaxle.

- install the 18 bolts.

Torque: 5.3 N·m (55 kgf·cm, 48 in.Vlbf)

9. Install engine under cover lh

10. Add automatic transaxle fluid

11. Inspect automatic transaxle fluid

Other materials:

Using the audio system

Optimal use of the audio system

Sound quality (treble/bass) and volume balance can be adjusted.

1 Displays the current mode

2 Changes the following setting

• Sound quality and volume balance

The sound quality and balance setting can be changed to produce the best sound.

• Automatic ...

Body panel undercoating areas

Apply pastar uwe or pastar uc to the chassis, floor underside, sheet metal

fitting weld points of the body, and

inside of the wheel house to prevent rust and noise, as well as protect the body

from flying rocks.

Hint:

work must be performed while wearing the appropriate protective ...

On–vehicle inspection

1. Inspect sliding roof function

check the slide opening operation (manual).

Turn the ignition switch on.

When keeping operating the sliding roof switch to the open side,

check that the roof glass will

slide and be fully opened.

check the slide closing ...