Toyota Corolla (E120) 2002–2008 Repair Manual / Brake / Skid control sensor

Toyota Corolla (E120): Skid control sensor

Replacement

Hint

: replace the rh side by the same procedure as the lh side.

1. Remove rear wheel

2. Remove rear brake drum sub–assy

3. Disconnect skid control sensor wire

- Disconnect the skid control sensor wire connector from the skid control sensor.

4. Remove rear axle hub & bearing assy lh

5. Remove skid control sensor

- Mount the rear axle hub in a soft jaw vise.

Notice

: replace the axle hub assembly if it is dropped or a strong shock is given to it.

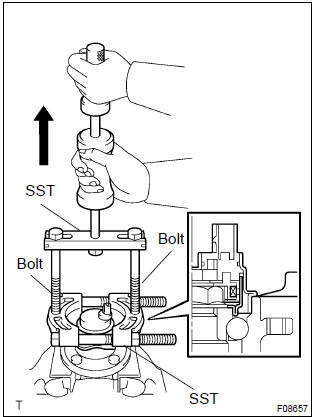

- using a pin punch and hammer, drive out the 2 pins and remove the 2 attachments from sst.

- using sst and 2 bolts (diameter: 12 mm, pitch: 1.5 Mm),

remove the skid control sensor from the rear axle hub.

Sst 09520–00031 (09520–00040), 09521–00020, 09950–00020

N

otice

:

- if a damage is inflicted to the sensor rotor, replace the axle hub assembly.

- Do not scratch the contacting surface of axle hub and speed sensor.

6. Install skid control sensor

- clean the contacting surface of the axle hub and a new

speed sensor.

Notice

: do not stick any foreign objects to the sensor rotor.

- place the speed sensor on the axle hub so that the connector makes the lowest position under the on–vehicle condition.

- Using sst and press, install the new speed sensor to the

axle hub.

Sst 09214–76011

7. Install rear axle hub & bearing assy lh

8. Connect skid control sensor wire

- Connect the skid control sensor wire connector to the skid control sensor.

9. Install rear brake drum sub–assy

10. Install rear wheel

torque: 103 nvm (1,050 Kgf·cm, 76 ft·lbf)

11. Inspect and adjust rear wheel alignment

12. Check abs speed sensor signal

Other materials:

Installing tire pressure

warning valves and transmitters

(vehicles with a

tire pressure warning system)

When replacing tires or wheels,

tire pressure warning valves and transmitters must also be

installed.

When new tire pressure warning

valves and transmitters are

installed, new ID codes must be

registered in the tire pressure

warning computer and the tire

pressure warning system must

be initialized. ...

Using the AUX port

To use the AUX port, connect a portable player, press the “AUDIO” button,

then select “AUX” to display the audio control screen.

Connecting a portable audio player

■Operating portable audio players connected to the multimedia system

The volume can be adjusted using the vehicle' ...

Inspection procedure

1 Check security indicator light

Remove the security indicator.

check the indicator light, as shown in the illustration and

table.

Standard:

2 Check wire harness (tvip ecu security indicator)

Disconnect the tvip ecu and security indicator connectors.

...