Toyota Corolla (E120) 2002–2008 Repair Manual / Exterior/interior trim / Roof drip side finish moulding center lh

Toyota Corolla (E120): Roof drip side finish moulding center lh

Replacement

Hint

:

- use the same procedures for the rh side and lh side.

- The installation procedures are the removal procedures in reverse order. However, only installation procedures requiring additional information are included.

1. Remove roof drip side finish moulding center lh

- Apply protective tape onto the circumference of the moulding for protection.

- using a remover for the roof moulding, release the engagements of the clips both in the front and rear ends of the moulding. Then remove the moulding.

Notice

:

- do not remove the clips.

- If clips are damaged during removal or removed accidentally, replace them.

2. Install roof drip side finish moulding clip no.1

Notice

: step 2 should be performed only when replacing the clips.

- remove the double–sided tape that remains on the mounting surface of the body, and then clean the surface with white gasoline.

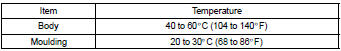

- using a heat light, heat the clip installation surfaces of the body.

Heating temperature:

Notice

: do not heat the body and moulding excessively.

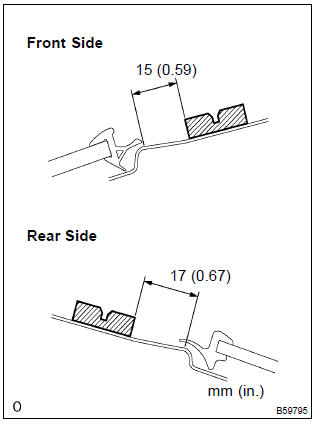

- set new clips in the positions as shown in the illustration,

and press–fit those clips by hand to install them.

Hint

: clips for the roof drip side finish moulding are supply parts.

- after press–fitting the clips, wait at last 30 minutes. Then install the moulding.

Hint

:

- initial hardening time: 30 minutes

- prefect hardening time: 24 hours

Other materials:

Registering a Bluetooth® device

Before using the Bluetooth® audio/phone, it is necessary to register a Bluetooth®

device in the system. You can register up to 5 Bluetooth® devices.

How to register a Bluetooth® device

1 Press and select “Bluetooth*”

using .

2 Press and select “BT Pairing”

using .

A passkey w ...

Before driving

Observe the following

before starting off in the

vehicle to ensure safety of

driving.

Floor mat

Use only floor mats designed

specifically for vehicles of the

same model and model year as

your vehicle. Fix them securely

in place onto the carpet.

1. Insert the retaining hooks

(clips) into the floor ma ...

Seat belt pretensioners (front seats)

The pretensioners help the seat belts to quickly restrain the occupants by retracting

the seat belts when the vehicle is subjected to certain types of severe frontal

or side collision.

The pretensioners do not activate in the event of a minor frontal impact, a minor

side impact, a rear impact ...