Toyota Corolla (E120): Check open circuit

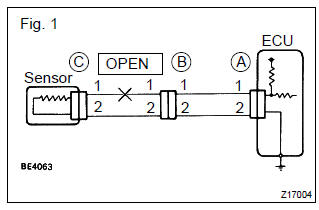

- For the open circuit in the wire harness in fig. 1, Perform a resistance check in step (b) or a voltage check in step (c) to locate the section.

- Check the resistance.

- Disconnect connectors a and c and measure the

resistance between them.

Resistance: 1 Ω or less

Hint

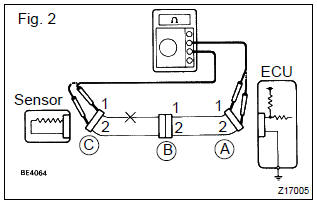

: measure the resistance while lightly shaking the wire harness vertically and horizontally. In the case of fig. 2: Between terminal 1 of connector a and terminal 1 of connector c " 10 kΩ

or higher between terminal 2 of connector a and terminal 2 of connector c " below 1 Ω

therefore, the cause is an open circuit between terminal 1 of connector a and terminal 1 of connector c.

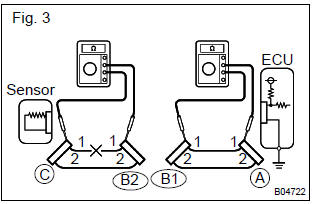

- Disconnect connector b and measure the resistance

between the connectors.

In the case of fig. 3: Between terminal 1 of connector a and terminal 1 of connector b1 " below 1 w between terminal 1 of connector b2 and terminal 1 of connector c " 10 kw therefore, the cause is an open circuit between terminal 1 of connector b2 and terminal 1 of connector c.

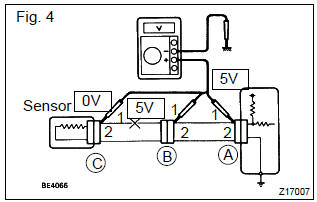

- Check the voltage.

- In a circuit in which voltage is applied (to the ecu

connector terminal), an open circuit can be checked

by conducting a voltage check.

As shown in fig. 4, With each connector still connected, measure the voltage between the body ground and terminal 1 of connector a at the ecu 5 v output terminal, terminal 1 of connector b, and terminal 1 of connector c, in that order.

- If the results are: 5 v: between terminal 1 of connector a and body ground 5 v: between terminal 1 of connector b and body ground 0 v: between terminal 1 of connector c and body ground therefore, the cause is an open circuit in the wire harness between terminal 1 of connector b and terminal 1 of connector c.

Other materials:

Vehicle information

This screen can be used to display the fuel consumption.

“Trip Information” or “Past Record” screen

Press “CAR” to display the “Trip Information” or “Past Record” screen.

Fuel consumption

■ Trip information

If the “Trip Information” screen does not appear, select â ...

Transmission valve body assy (atm)

Replacement

1. Remove engine under cover lh

2. Drain automatic transaxle fluid

remove the drain plug, gasket and drain atf.

install a new gasket and drain plug.

Torque: 17.5 Nvm (178 Kgf·cm, 13 ft·lbf)

3. Remove automatic transaxle oil pan sub–assy

Remove the 18 ...

General maintenance

Listed below are the general

maintenance items that

should be performed at the

intervals specified in the

"Owner's Warranty Information

Booklet" or "Owner's

Manual Supplement/Scheduled

Maintenance Guide". It

is recommended that any

problem you notice should

be brought to the attention

of your Toyota ...