Toyota Corolla (E120): Replacement

1. Remove battery

2. Remove battery carrier

- Remove the 4 bolts and battery carrier.

3. Disconnect floor shift cable transmission control shift

- Remove the nut from the control shaft lever.

- disconnect the control cable from the control shaft lever.

- remove the clip and disconnect the control cable from the control cable bracket.

4. Remove park/neutral position switch assy

- Disconnect the park/neutral position switch connector.

- remove the nut, washer and control shaft lever.

- pry out the lock plate and remove the manual valve shaft nut.

- remove the 2 bolts and pull out the park/neutral position switch.

5. Install park/neutral position switch assy

- Install the park/neutral position switch to the manual valve shaft.

- temporarily install the 2 bolts.

- place a new lock plate and tighten the nut.

Torque: 5.5 Nvm (56 Kgf·cm, 49 in.Vlbf)

- temporarily install the control shaft lever.

- Turn the lever counterclockwise until it stops, then turn it clockwise 2 notches.

- remove the control shaft lever.

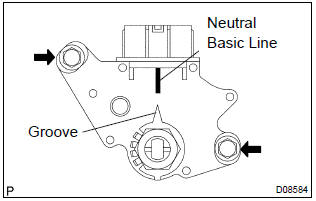

- Align the groove with neutral basic line.

- hold the switch in position and tighten the 2 bolts.

Torque: 5.5 Nvm (56 Kgf·cm, 49 in.Vlbf)

- Using a screwdriver, stake the nut with the lock plate.

- Install the control shaft lever, washer and nut.

Torque: 12.5 Nvm (127 Kgf·cm, 9 ft·lbf)

- connect the park/neutral position switch connector.

6. Install floor shift cable transmission control shift

- Temporarily install the control cable to the control shaft lever with nut.

- install the control cable and clip to the bracket.

7. Install battery carrier

- Install the battery carrier and 4 bolts.

Torque: 13 nvm (132 Kgf·cm, 10 ft·lbf)

8. Adjust shift lever position

9. Inspect shift lever position

10. Inspect park/neutral position switch assy

Other materials:

Inspection procedure

1 Check un–lock warning switch assy

Disconnect the key unlock warning switch connector.

check the continuity between the terminals of the key unlock

warning switch connector, as shown in the illustration

and table.

Standard:

2 Check wire harness (tvip ecu unlock warni ...

Overhaul

1. Remove control shift lever bush

Remove the control shift lever bush from the selecting

bellcrank assy.

2. Remove selecting bellcrank dust cover no.1

Remove the selecting bellcrank dust cover no.1 From the

selecting bellcrank assy.

3. Remove selecting bell crank no.2

...

Checking the messages

1 Display the “Message Inbox” screen.

2 Select the desired message from the list.

3 Check that the message is displayed.

1 E-mails: Select “Mark Unread” or “Mark Read” to mark mail unread or read on

the message inbox screen.

This function is available when “Update Message Read S ...