Toyota Corolla (E120): Repair

1. Steering off center repair procedure

- Inspect steering wheel off center.

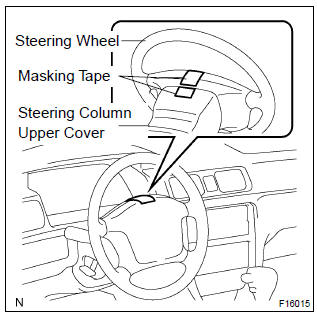

- Apply masking tape on the top center of the steering wheel and steering column upper cover.

- Driving the vehicle on a straight line for 100 meters at a constant speed of 35 mph (56 km/h), and hold the steering wheel to maintain the course.

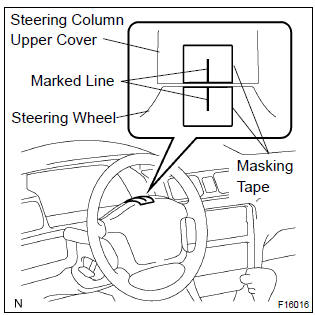

- Draw a line on the masking tape as shown in the illustration.

- Turn the steering wheel to its straight position.

Hint

: refer to the upper surface of the steering wheel, steering spoke and srs airbag line for the straight position.

- Draw a new line on the masking tape or the steering wheel as shown in the illustration.

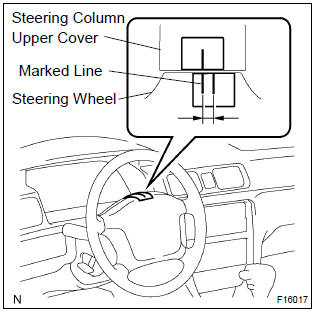

- Measure the distance between the 2 lines on the masking tape of the steering wheel.

- Convert the measured distance to steering angle.

Measured distance 1 mm (0.04 In.) = Steering angle approximately 1 deg.

Hint

: make a note of the steering angle.

- adjust steering angle.

Notice

: the adjustment method for steering angle varies depending on the models. Check whether it is type a or b.

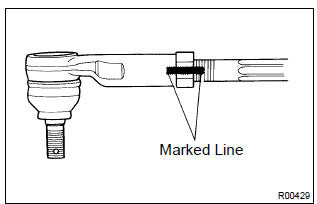

- Draw a line on the rh and lh tie rod and rack ends where it can easily be seen.

- Using a paper gauge, measure the distance from rh and lh tie rod ends to the rack end screws.

Hint

:

- measure the rh side and lh side.

- Make a note of the measured values.

- Remove the rh and lh boot clips from the rack boots.

- Loosen the rh and lh lock nuts.

- Turn the rh and lh rack end by the same amount

(but in different directions) according to the steering

angle.

1 Turn 360 deg. Of rack end (1.5 Mm (0.059 In.) Horizontal movement) – 12 deg. Of steering angle.

- Tighten the rh and lh lock nuts by the specified

torque.

Torque: 74 n·m (750 kgf·cm, 54 ft·lbf)

Notice

: make sure that the difference in length between rh and lh tie rod ends and rack end screws are within 1.5 Mm (0.059 In.).

- Install the rh and lh boot clips.

Other materials:

Meter display

■ Locations of gauges and meters

The units of measure may differ depending on the intended destination of

the vehicle.

Tachometer

Displays the engine speed in revolutions per minute

Outside temperature

Displays the outside temperature within the range of -40ºF (-40ºC) to 140ºF

(60ºC)

...

Bluetooth® Audio

Operating a Bluetooth® enabled portable player

1 Power

2 Volume

3 Select an album, fast-forward or reverse

4 Repeat play

5 Random playback

6 Selecting an item

7 Displays text message

8 Playback

9 Playback/pause

10 Search playback

11 Select a track

Selecting an album

Press (

) or ...

Circuit description

The p/t squib (rh) circuit consists of the airbag sensor assy center and seat

belt pretensioner (rh).

It causes the srs to deploy when the srs deployment conditions are satisfied.

Dtc b0130/63 is recorded when a short is detected in the p/t squib (rh) circuit.

Wiring diagram

...