Toyota Corolla (E120) 2002–2008 Repair Manual / Rear suspension / Rear wheel alignment

Toyota Corolla (E120): Rear wheel alignment

Inspection

1. Inspect tire

2. Measure vehicle height

Notice

: before inspecting the wheel alignment, adjust the vehicle height to the specified value.

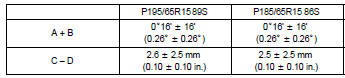

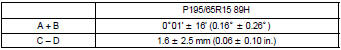

3. Inspect toe–in

Toe–in: usa, canada:

Mexico:

If the toe–in is not within the specified value, inspect and replace the suspension parts as necessary.

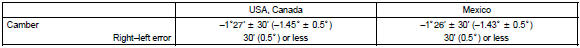

4. Inspect camber

- install the camber–caster–kingpin gauge or position vehicle on wheel alignment tester.

- inspect the camber.

Camber:

If the measured value is not within the specified value, inspect the suspension parts for damage and/or wear and replace them if necessary become camber is not adjustable.

Other materials:

Foreword

This repair manual has been prepared to provide essential information

on body panel repair methods (including cutting and

welding operations, but excluding painting) for the toyota

corolla

Applicable models: aze141 series

zre142 series

This manual consists of body repair methods, exploded diag ...

Checking tires

Check if the treadwear indicators

are showing on the tires.

Also check the tires for uneven

wear, such as excessive wear

on one side of the tread.

Check the spare tire condition

and pressure if not rotated.

New tread

Worn tread

Treadwear indicator

The location of treadwear indicators

is show ...

Power door lock control system

Symptom

Suspected area

All doors are not operated by driver’s door key cylinder

interlocked with key

Door lock control switch

Front door lock assy lh

Wire harness

Integration relay

Key confinement prevention function does ...