Toyota Corolla (E120): Overhaul

1. Drain brake fluid

Notice

: wash the brake fluid off immediately if it comes into contact with any painted surface.

2. Remove air cleaner cap sub–assy

3. Remove brake master cylinder sub–assy

- disconnect the brake fluid level switch connector from master cylinder reservoir sub–assy.

- m/t: slide the clip and disconnect the clutch reservoir tube no.1 From master cylinder reservoir sub–assy.

- Using sst, disconnect the 2 brake tubes from the master

cylinder.

Sst 09023–00100

- Using sst, disconnect the 2 or 3 brake tubes from the

no.1 Way.

Sst 09023–00100

- Remove the 2 nuts, and pull out the master cylinder, no.1 Way and vacuum check valve bracket.

4. Remove brake master cylinder reservoir sub–assy

- remove the reservoir stopper screw and master cylinder reservoir sub–assy.

- remove the 2 cylinder reservoir grommets.

5. Remove brake master cylinder kit

- hold the master cylinder in the vise with the 2 aluminum plates in between.

- remove the o–ring.

- Push in the piston and remove the snap ring with snap ring pliers.

- Push in the piston and remove the piston stopper bolt and gasket.

- remove the no.1 Piston sub–assy by hand, pulling straight out not at an angle.

Notice

: if being pulled out at an angle, the piston may damage the cylinder bore.

- Place a cloth and 2 wooden blocks on the work table and lightly edges until the no.2 Piston sub–assy drops out of the cylinder.

Notice

: if being pulled out at an angle, the piston may damage the cylinder bore.

Hint

: make sure that the distance (a) from the cloth to the top of the blocks is at least 100 mm (3.94 In.).

6. Inspect brake master cylinder

- check the cylinder bore for rust or scoring.

7. Install brake master cylinder kit

- hold the master cylinder in the vise with the 2 aluminum plates in between.

- apply the lithium soap base glycol grease to the no.1 And no.2 Piston sub–assy.

- install the no.2 And no.1 Piston sub–assy to the master cylinder.

Notice

:

- if being inserted at an angle, the piston may damage the cylinder bore.

- Be careful not to damage the rubber lips on the pistons.

- Push in the piston and install a new gasket and a new piston

stopper bolt.

Torque: 10 nvm (102 Kgf·cm, 7 ft·lbf)

- Push in the piston and install the snap ring with snap ring pliers.

- apply the lithium soap base glycol grease to a new o– ring, and install the o–ring to the master cylinder.

8. Install brake master cylinder reservoir sub–assy

- apply the lithium soap base glycol grease to 2 brake master cylinder reservoir grommets.

- install the master cylinder reservoir with the screw.

Torque: 1.8 Nvm (18.4 Kgf·cm, 15.9 In.Vlbf)

9. Inspect and adjust brake booster push rod

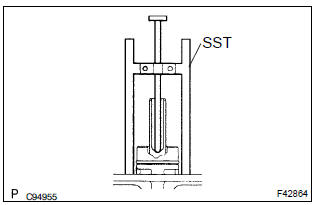

- Apply the chalk to the flat surfaced tip of the sst pin.

- set sst on the master cylinder and lower the pin of the

sst until it slightly touches the piston.

Sst 09737–00013

- Turn sst upside down and place it on the brake booster.

Sst 09737–00013 clearance: 0 mm (0 in.)

Hint

:

- if there is a space between the sst main body and the booster shell (chalk is applied to the booster push rod), it means that the clearance is too small.

- If chalk is not applied to the booster push rod after placing the sst on the brake booster, it means that the clearance is too large.

- If clearance is outside of the specified range, fix the push

rod using sst and adjust the length of the protruding adjusting

bolt.

Sst 09737–00020

Hint

: when adjusting the push rod, depress the brake pedal sufficiently so that the push rod sticks out.

10. Install brake master cylinder sub–assy

- install the master cylinder, no.1 Way and vacuum check

valve bracket with the 2 nuts.

Torque: 12.5 Nvm (127 Kgf·cm, 9 ft·lbf)

- Using sst, connect the 2 or 3 brake tubes to the no.1

Way.

Sst 09023–00100

torque: 15.2 Nvm (155 Kgf·cm, 11 ft·lbf)

- Using sst, connect the 2 brake tubes to the master cylinder.

Sst 09023–00100

torque: 15.2 Nvm (155 Kgf·cm, 11 ft·lbf) - m/t: connect the clutch reservoir tube no.1 With the clip to master cylinder reservoir sub–assy.

- connect the brake fluid level switch connector to master cylinder reservoir sub–assy.

11. Install air cleaner cap sub–assy

12. Fill reservoir with brake fluid

13. Bleed master cylinder

sst 09023–00100

14. Bleed brake line

15. Check fluid level in reservoir

16. Check brake fluid leakage

Other materials:

For vehicles equipped with srs airbag and seat belt pretensioner

Hint:

the vehicle is equipped with an srs (supplemental restraint system), such as the

horn button assembly,

the instrument panel passenger airbag assembly, the front seat airbag assembly,

the center airbag sensor

assembly, the front airbag sensor, the side airbag sensor and the seat belt

p ...

Cooling

Preparation

Recomended tools

Equipment

Coolant

...

Out side moulding

Replacement

Hint:

use the same procedures for the rh side and lh side.

1. Remove outside moulding

Put protective tape around the moulding.

insert a piano wire between the vehicle body and moulding.

tie objects that can serve as handles (for example, wooden

blocks) to all ...