Toyota Corolla (E170) 2014–2019 Owners Manual / Driving / Operating the lights and wipers / Headlight switch / Operating instructions

Toyota Corolla (E170): Operating instructions

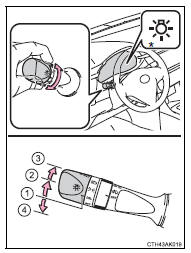

Turning the end of the lever turns on the lights as follows: ► Type A

1  The daytime running lights turn

on.

The daytime running lights turn

on.

2  The side marker, parking, tail,

license plate, daytime running lights and instrument panel lights turn on.

The side marker, parking, tail,

license plate, daytime running lights and instrument panel lights turn on.

3  The headlights and all the lights

listed above (except daytime running lights) turn on.

The headlights and all the lights

listed above (except daytime running lights) turn on.

4  The daytime running lights turn

off.

The daytime running lights turn

off.

*: Vehicles with a multi-information display

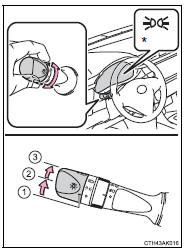

► Type B

1  The daytime running lights turn

on

The daytime running lights turn

on

2  The side marker, parking, tail,

license plate, daytime running lights and instrument panel lights turn on.

The side marker, parking, tail,

license plate, daytime running lights and instrument panel lights turn on.

3  The headlights and all the

lights listed above (except daytime running lights) turn on.

The headlights and all the

lights listed above (except daytime running lights) turn on.

*: Vehicles with a multi-information display

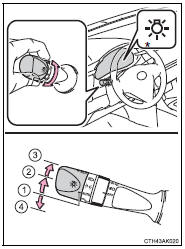

► Type C

1  The headlights and all the lights

listed below turn on and off automatically.

The headlights and all the lights

listed below turn on and off automatically.

(Vehicles without a smart key system: When the engine switch is in the “ON” position) (Vehicles with a smart key system: When the engine switch is in IGNITION ON mode)

2  The side marker, parking, tail,

license plate, daytime running lights and instrument panel lights turn on.

The side marker, parking, tail,

license plate, daytime running lights and instrument panel lights turn on.

3  The headlights and all the lights

listed above (except daytime running lights) turn on.

The headlights and all the lights

listed above (except daytime running lights) turn on.

4  The daytime running lights turn

off.

The daytime running lights turn

off.

*: Vehicles with a multi-information display

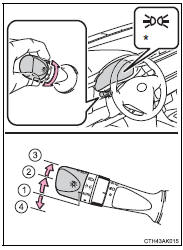

► Type D

1  The headlights and all the lights

listed below turn on and off automatically.

The headlights and all the lights

listed below turn on and off automatically.

(Vehicles without a smart key system: When the engine switch is in the “ON” position) (Vehicles with a smart key system: When the engine switch is in IGNITION ON mode)

2  The side marker, parking, tail,

license plate, daytime running lights and instrument panel lights turn on.

The side marker, parking, tail,

license plate, daytime running lights and instrument panel lights turn on.

3  The headlights and all the lights

listed above (except daytime running lights) turn on.

The headlights and all the lights

listed above (except daytime running lights) turn on.

4  The daytime running lights turn

on.

The daytime running lights turn

on.

*: Vehicles with a multi-information display

Other materials:

Inspection procedure

1 Inspect fuse(stop)

Turn the ignition switch to off.

remove the stop fuse from the instrument panel j/b.

check continuity of the stop fuse.

Ok: continuity

2 Inspect stop lamp switch assy

Disconnect the stop lamp switch assy connector.

check continuity betw ...

Engine rear oil seal

Replacement

1. Remove manual transaxle assy (m/t transaxle)

2. Remove automatic transaxle assy (a/t transaxle)

3. Remove clutch cover assy (m/t transaxle)

remove the 6 bolts and clutch cover.

4. Remove clutch disc assy (m/t transaxle)

5. Remove flywheel sub–assy (m/t transaxle ...

Combination meter assy

Overhaul

Hint: components:

1. Remove meter hood sub–assy

2. Remove combination meter assy

Remove the screw.

disengage the 2 clips as shown in the illustration.

disconnect the connector, then remove the combination

meter.

3. Remove combination meter glass

Di ...