Toyota Corolla (E120): On–vehicle inspection

1. Inspect brake booster

- Airtightness check.

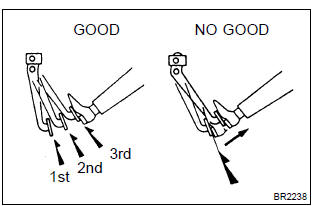

- Start the engine and stop it after 1 or 2 minutes. Depress

the brake pedal several times slowly.

Hint

: if the pedal goes down farthest at the 1st time, but gradually rises after the 2nd or 3rd time, the booster is airtight.

- Depress the brake pedal while the engine is running,

and stop the engine with the pedal depressed.

Hint

: if there is no change in the pedal reserve distance after holding the pedal for 30 seconds, the booster is airtight.

- Operating check.

- Depress the brake pedal several times with the ignition switch off and check that there is no change in the pedal reserve distance.

- Depress the brake pedal and start the engine.

Hint

: if the pedal goes down slightly, operation is normal.

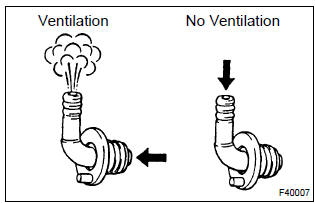

2. Inspect vacuum check valve

- check vacuum check valve.

- Slide the clip and disconnect the vacuum hose.

- Remove the vacuum check valve.

- Check that there is ventilation from the booster to engine, and no ventilation from the engine to the booster.

- If any fault is found, replace the vacuum check valve.

Other materials:

Inspection procedure

1 Inspect fuse(ecu–ig fuse)

Remove ecu–ig fuse from the instrument panel j/b.

check continuity of ecu–ig fuse.

Ok:

continuity

2 Inspect battery

Ok:

voltage: 10 – 14 v

3 Inspect skid control ecu connector(ig1 terminal voltage)

In case of using hand–held te ...

Location of the storage features

Bottle holders/door pockets

Open trays (if equipped)

Glove box

Cup holders (if equipped)

Console box

WARNING

■Items that should not be left

in the storage spaces

Do not leave glasses,

spray cans in the storage spaces,

as this may cause the following

when cabin temperature becomes

high:

...

Removal and installation of fuel control parts

Place for removing and installing of fuel system parts

work in a place with good air ventilation and without anything

flammable such as welder, grinder,

drill, electric motor or stove in the surroundings.

Never work in a place such as a pit or nearby a pit, as there is a ...