Toyota Corolla (E120): On–vehicle inspection

1. Inspect brake booster

- Airtightness check.

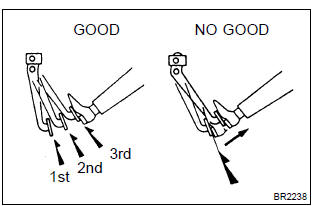

- Start the engine and stop it after 1 or 2 minutes. Depress

the brake pedal several times slowly.

Hint

: if the pedal goes down farthest at the 1st time, but gradually rises after the 2nd or 3rd time, the booster is airtight.

- Depress the brake pedal while the engine is running,

and stop the engine with the pedal depressed.

Hint

: if there is no change in the pedal reserve distance after holding the pedal for 30 seconds, the booster is airtight.

- Operating check.

- Depress the brake pedal several times with the ignition switch off and check that there is no change in the pedal reserve distance.

- Depress the brake pedal and start the engine.

Hint

: if the pedal goes down slightly, operation is normal.

2. Inspect vacuum check valve

- check vacuum check valve.

- Slide the clip and disconnect the vacuum hose.

- Remove the vacuum check valve.

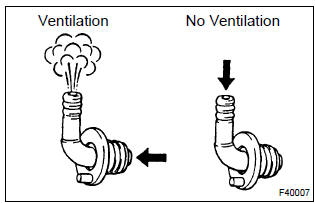

- Check that there is ventilation from the booster to engine, and no ventilation from the engine to the booster.

- If any fault is found, replace the vacuum check valve.

Other materials:

Maintenance requirements

To ensure safe and economical driving, day-to-day care and regular maintenance

are essential. It is the owner’s responsibility to perform regular checks. Toyota

recommends the following maintenance:

General maintenance

General maintenance should be performed on a daily basis. This can be don ...

Roof drip side finish moulding center lh

Replacement

Hint:

use the same procedures for the rh side and lh side.

The installation procedures are the removal procedures in reverse

order. However, only installation

procedures requiring additional information are included.

1. Remove roof drip side finish moulding center lh

...

Inspection procedure

1 Check source voltage

Measure the voltage of the battery.

Ok:

voltage: 10 – 14 v

2 Check air bag sensor assy center

Disconnect the negative (–) terminal cable from the battery, and wait at

least for 90 seconds.

disconnect the connectors from the airbag sensor assy ...