Toyota Corolla (E120) 2002–2008 Repair Manual / Starting & charging / Charging system / On–vehicle inspection

Toyota Corolla (E120): On–vehicle inspection

1. Check battery electrolyte level

- Check the electrolyte quantity of each cell (maintenance–free battery).

- If under the lower level, replace the battery (or add distilled water if possible) and check the charging system.

- check the electrolyte quantity of each cell (except maintenance–free battery).

- If under the lower level, add distilled water.

2. Check battery specific gravity (except maintenance–free battery)

- Check the specific gravity of each cell.

Standard specific gravity: 1.25 – 1.29 At 20 c (68 f)

Hint

: if the specific gravity is less than specification, charge the battery.

3. Check battery voltage

- After having driven the vehicle and in the case that 20 minutes have not passed after having stopped the engine, turn the ignition switch on and turn on the electrical system (headlight, blower motor, rear defogger etc.) For 60 seconds to remove the surface charge.

- turn the ignition switch off and turn off the electrical systems.

- measure the battery voltage between the negative (–)

and positive (+) terminals of the battery.

Standard voltage: 12.5 – 12.9 V at 20 c (68 f)

Hint

: if the voltage is less than specification, charge the battery.

- Check the indicator as shown in the illustration.

Hint

:

- blue: ok

- white: charging necessary

- red: insufficient water

4. Check battery terminals, fusible link and fuses

- Check that the battery terminals are not loose or corroded.

- check the fusible link, h–fuses and fuses for continuity.

5. Inspect drive belt

- Visually check the belt for excessive wear, frayed cords etc.

Hint

:

- if any defect has been found, replace the drive belt.

- Cracks on the rib side of a belt are considered acceptable.

If the belt has chunks missing from the ribs, it should be replaced.

- Check that it fits properly in the ribbed grooves.

Hint

: check with your hand to confirm that the belt has not slipped out of the groove on the bottom of the pulley.

6. Visually check alternator wiring

- check that the wiring is in good condition.

7. Listen for abnormal noises from alternator

- check that there is no abnormal noise from the alternator while the engine is running.

8. Inspect charge warning light circuit

- turn the ignition switch on. Check that the charge warning light comes on.

- start the engine. Check that the light goes off.

Hint

: if the light does not operate as specified, troubleshoot the charge warning light circuit.

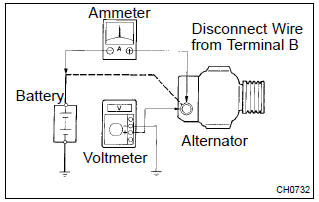

9. Inspect charging circuit without load

- if a battery/alternator tester is available, connect the tester to the charging circuit as permanufacturer’s instructions.

- If a tester is not available, connect a voltmeter to the charging circuit as follows.

- Disconnect to the wire from terminal b of the alternator and connect it to the negative (–) lead of the ammeter.

- Connect the positive (+) lead of the ammeter to terminal b of the alternator.

- Connect the positive (+) lead of the voltmeter to terminal b of the alternator.

- Ground the negative (–) lead of the voltmeter.

- Check the charging circuit (denso made).

- With the engine running from idle to 2,000 rpm,

check the reading on the ammeter and voltmeter.

Standard amperage: 10 a or less standard voltage: 12.9 – 14.9 V

10. Inspect charging circuit with load

- with the engine running at 2,000 rpm, turn on the high beam headlights and place the heater blower switch at ”hi”.

- check the reading on the ammeter.

Standard amperage: 30 a or more

Hint

:

- if the ammeter reading is less than standard amperage, repair the alternator.

- If the battery is fully charged, the indication will sometimes be less than standard amperage.

Other materials:

Using the radio

Radio operation

Select “AM” or “FM” to begin listening to the radio.

1 Power

2 Volume

3 Station selectors

4 Adjust frequency or select an item

5 AM/FM mode button

6 Scan for receivable stations

7 Seek a frequency

Setting station presets

1Search for a desired station by turning

...

Safety information for children

Observe the following precautions when children are in the vehicle.

Use a child restraint system appropriate for the child, until the child becomes

large enough to properly wear the vehicle’s seat belt.

● It is recommended that children sit in the rear seats to avoid accidental contact

...

Inspection procedure

1 Inspect dlc3 terminal voltage

Turn the ignition switch to on.

measure voltage between terminals 13 (tc) and 4 (cg) of

dlc3.

Ok:

voltage: 10 – 16 v

2 Check harness and connector(between cruise control ecu assy

and dlc3)

Check for open and short circuit in harness ...