Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Toyota vehicle intrusion protection system / Horn relay circuit / Inspection procedure

Toyota Corolla (E120): Inspection procedure

1 Check low pitched horn assy

- Connect the positive (+) lead from the battery to the terminal and negative (–) lead to the horn body, and check that the horn blows.

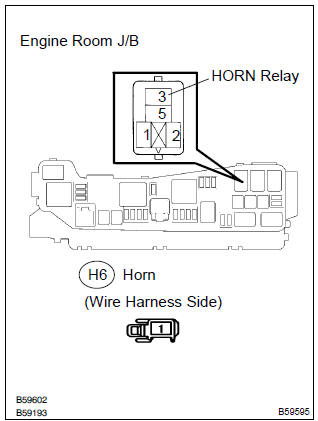

2 Check relay (marking: horn)

- Remove the relay from the engine room j/b.

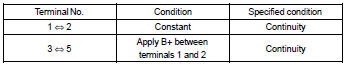

- check the horn relay continuity, as shown in the illustration and table.

Standard:

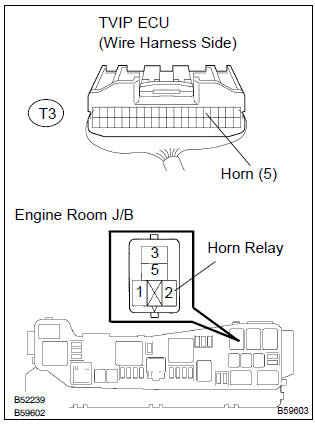

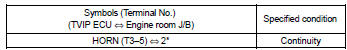

3 Check wire harness (tvip ecu engine room j/b)

- Remove the horn relay from the engine room j/b.

- check the continuity between the terminals of the tvip ecu and engine room j/b connectors, as shown in the illustration and table.

Standard:

*: Horn relay terminal

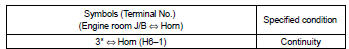

4 Check wire harness (engine room j/b horn)

- Check the continuity between the terminals of the engine room j/b and horn connectors, as shown in the illustration and table.

Standard:

*: Horn relay terminal.

Check and replace tvip ecu

Other materials:

Dtc check/clear

1. Dtc check (normal mode)

Notice:

hand–held tester only:

when the diagnostic system is switched from the normal

mode to the check mode, all the dtcs and freeze frame

data recorded in the normal mode will be erased. So before

switching modes, always check the dtcs and freeze frame

data, and ...

Electronic control

Removal and installation of battery terminal

before performing electrical work, disconnect the

battery negative (–) terminal cable beforehand so

as to prevent burnt–out damage by short.

When disconnecting and installing the terminal

cable, turn the ignition switch an ...

Inspection procedure

Hint:

if different dtcs related to different systems that have terminal e2

as the ground terminal are output

simultaneously, terminal e2 may be open.

If dtc p0441 (purge flow), p0446 (vsv for ccv), p0451, p0452 or p0453

(evaporative pressure

sensor) is output with dtc p0442 or p0456, ...