Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Toyota vehicle intrusion protection system / Ignition switch circuit / Inspection procedure

Toyota Corolla (E120): Inspection procedure

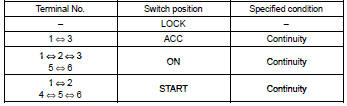

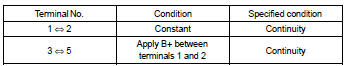

1 Check ignition or starter switch assy

- Check the ignition switch, as shown in the illustration and table.

Standard:

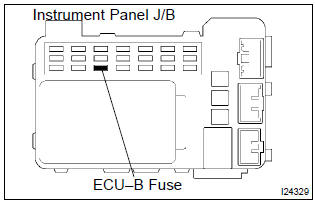

2 Check fuse (ecu–b)

- Remove the fuse from the instrument panel j/b.

- check the continuity of the fuse.

Standard: continuity

3 Check relay (marking: ig1)

- Remove the relay from the instrument j/b.

- inspect the relay continuity, as shown in the illustration and table.

Standard:

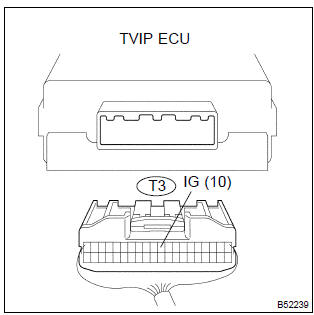

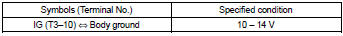

4 Check tvip ecu

- Disconnect the tvip ecu connector.

- turn the ignition switch on.

- measure the voltage between the terminal of the ecu connector and the body ground, as shown in the illustration and table.

Standard:

Check and replace tvip ecu

Other materials:

Replacement

Hint:

for parking brake cable assy no.2, Perform the same procedure to the parking

brake cable assy no.3.

1. Remove rear wheel

2. Remove rear brake drum sub–assy

3. Remove rear brake automatic adjust lever lh

4. Remove front brake shoe

sst 09718–00010

5. Remove parking brake sho ...

Engine (ignition) switch (vehicles

with a smart key system)

Performing the following

operations when carrying

the electronic key on your

person starts the engine or

changes engine switch

modes.

Starting the engine

1. Check that the parking brake

is set.

2. Check that the shift lever is in

P.

3. Firmly depress the brake

pedal.

and a message will be display ...

Fog light switch

The fog lights secure excellent visibility in difficult driving conditions,

such as in rain and fog.

1 Turns the front fog lights off

2 Turns the front fog lights on

*1: For U.S.A.

*2: For Canada

■Fog lights can be used when

The headlights are on in low beam. ...