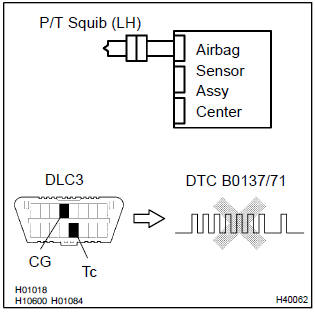

Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Supplemental restraint system / Short in p/t squib (lh) circuit (to

ground) / Inspection procedure

Toyota Corolla (E120): Inspection procedure

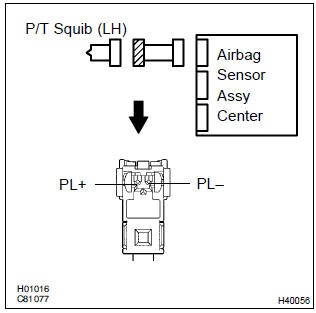

1 Check p/t squib(lh) circuit(airbag sensor assy center – front seat outer belt assy lh)

- Disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- disconnect the connectors between the airbag sensor assy center and the seat belt pretensioner (lh).

- for the connector (on the seat belt pretensioner side) between

the airbag sensor assy center and the seat belt pretensioner

(lh), measure the resistance between pl+ and

body ground.

Ok: resistance: 1 mΩ or higher

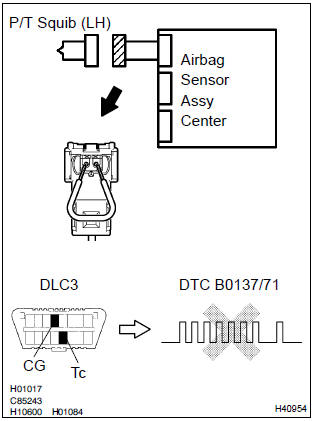

2 Check air bag sensor assy center

Sst 09843–18040

- Connect the connector to the airbag sensor assy center.

- using a service wire, connect pl+ and pl– of the connector (on the seat belt pretensioner side) between the airbag sensor assy center and the seat belt pretensioner (lh).

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b0137/71 is not output.

Hint

: codes other than code b0137/71 may be output at this time, but they are not relevant to this check.

3 Check p/t squib (lh)

Sst 09843–18040

- Turn the ignition switch to lock.

- disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- connect the seat belt pretensioner (lh) connector.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b0137/71 is not output.

Hint

: codes other than code b0137/71 may be output at this time, but they are not relevant to this check.

4 Use simulation method to check

Replace all srs components including the wire harness

Other materials:

Setup menu

You can adjust the multimedia system to your desired settings.

Display “Setup” screen

Press the “SETUP” button to display the “Setup” screen.

1 Select to adjust the settings for operation sounds, screen animation, etc.

2 Select to set the voice settings.

3 Select to adjust the s ...

Inspection procedure

Hint:

if dtcs p0115, p0116, p0117, p0118 and p0125 are output

simultaneously, the engine coolant temperature

sensor circuit may be open or short. Perform the troubleshooting of dtc

p0115, p0117 or

p0118 first.

Read freeze frame data using the hand-held tester or the obd ii scan

to ...

Using a flat bed truck

If you use chains or cables to tie down your vehicle, the angles shaded in black

must be 45°.

Do not overly tighten the tie downs or the vehicle may be damaged.

■Before emergency towing

1 Vehicles without a smart key system: Put the engine switch in the “ACC” (engine

off) or “O ...