Toyota Corolla (E120): Inspection procedure

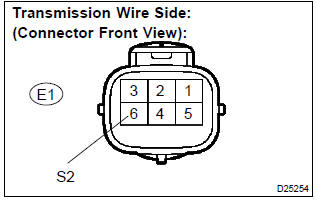

1 Inspect transmission wire(s2)

- Disconnect the transmission wire connector from the transaxle.

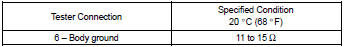

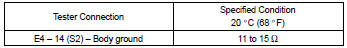

- measure the resistance according to the value(s) in the table below.

Standard:

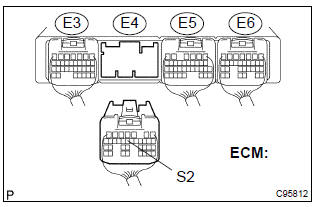

2 Check harness and connector(transmission wire – ecm)

- Connect the transmission connector to the transaxle.

- disconnect the connector from the ecm.

- measure the resistance according to the value(s) in the table below.

Standard:

Replace ecm

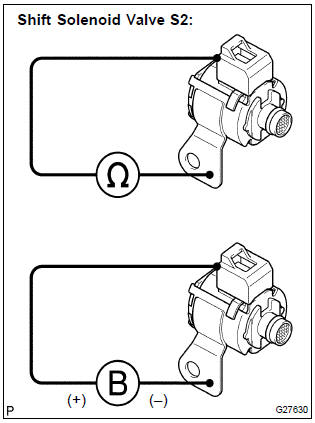

3 Inspect shift solenoid valve(s2)

- Remove the shift solenoid valve s2.

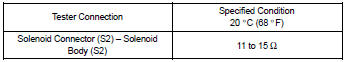

- measure the resistance according to the value(s) in the table below.

Standard:

- Connect the positive (+) battery lead to the solenoid connector terminal, and the negative (–) battery lead to the solenoid body for checking the solenoid valve operation.

Standard: the solenoid makes an operating noise.

Repair or replace transmission wire

Other materials:

Follow the correction procedures. (vehicles with a smart key system and with

a drive monitor display)

After taking the specified steps to correct the suspected problem, check that

the warning light turns off.

■SRS warning light

This warning light system monitors the airbag sensor assembly, front impact

sensors, side impact sensors (front door), side impact sensors (front), side impac ...

Circuit description

The srs warning light is located on the combination meter.

When the srs is normal, the srs warning light lights up for approx. 6 Seconds

after the ignition switch is

turned from the lock position to on position, and then turns off automatically.

If there is a malfunction is the srs, the srs ...

Meter display

■ Locations of gauges and meters

The units of measure may differ depending on the intended destination of

the vehicle.

Tachometer

Displays the engine speed in revolutions per minute

Outside temperature

Displays the outside temperature within the range of -40ºF (-40ºC) to 140ºF

(60ºC)

...