Toyota Corolla (E120) 2002–2008 Repair Manual / Front suspension / Front wheel alignment

Toyota Corolla (E120): Front wheel alignment

Adjustment

1. Inspect tire

2. Measure vehicle height

Vehicle height:

Measuring points:

a: ground clearance of front wheel center

b: ground clearance of lower suspension arm front

bolt center

c: ground clearance of axle beam set bolt center

d: ground clearance of rear wheel center

Notice

: before inspecting the wheel alignment, adjust the vehicle height to the specified value. If the vehicle height is not the specified value, try to adjust it by pushing down on or lifting the body.

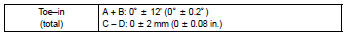

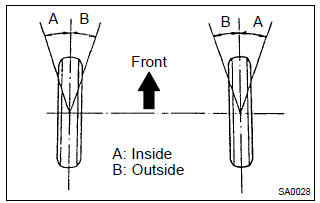

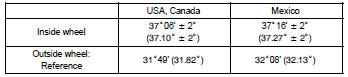

3. Inspect toe–in

Toe–in:

If the toe–in is not within the specified value, adjust it at the rack ends.

4. Adjust toe–in

- remove the rack boot set clips.

- loosen the tie rod end lock nuts.

- turn the right and left rack ends by an equal amount to adjust the toe–in.

Hint

: try to adjust the toe–in to the center of the specified value.

- Make sure that the lengths of the right and left rack ends

are the same.

Rack end length difference: 1.5 Mm (0.059 In.) Or less

- torque the tie rod end lock nuts.

Torque: 74 n·m (755 kgf·cm, 55 ft·lbf)

- place the boots on the seats and install the clips.

Hint

: make sure that the boots are not twisted.

5. Inspect wheel angle

- Turn the steering wheel fully and measure the turning angle.

Wheel turning angle:

If the right and left inside wheel angles differ from the specified value, check the right and left rack end lengths.

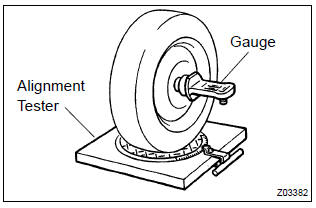

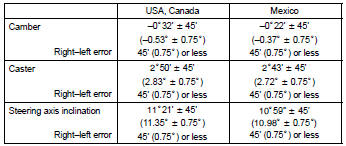

6. Inspect camber, caster and steering axis inclination

- Install the camber–caster–kingpin gauge or position vehicle on wheel alignment tester.

- inspect the camber, caster and steering axis inclination.

Camber, caster and steering axis inclination:

If the caster and steering axis inclination are not within the specified values, after the camber has been correctly adjusted, recheck the suspension parts for damaged and/or worn out parts.

7. Adjust camber

Notice

: after the camber has been adjusted, inspect the toe–in.

- remove the front wheel.

- Remove the 2 nuts on the lower side of the shock absorber

assy front lh.

Notice

: when removing nut, stop the bolt from rotating and loosen the nut.

- clean the installation surfaces of the shock absorber assy front lh and the steering knuckle.

- temporarily install the 2 nuts.

- Adjust the camber by pushing or pulling the lower side of the shock absorber in the direction in which the camber adjustment is required.

- tighten the nuts.

Torque: 153 nvm (1,560 Kgf·cm, 113 ft·lbf)

- install the front wheel.

Torque: 103 n·m (1,050 kgf·cm, 76 ft·lbf)

- Check the camber.

Hint

:

- try to adjust the camber to the center of the specified value.

- Adjusting value for the set bolts is –1 30’ – 0 30’ (–1.5 – 0.5 ).

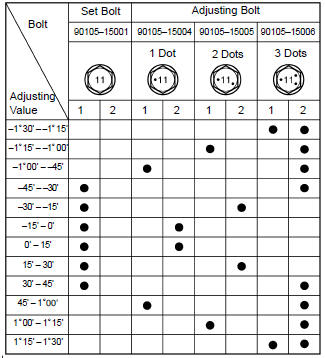

If the camber is not within the specified value, using the following table, estimate how much additional camber adjustment will be required, and select the camber adjusting bolt.

- Perform the steps mentioned above again. At step (e), replace 1 or 2 selected bolts.

Hint

: when replacing the 2 bolts, replace 1 bolt at a time.

Other materials:

Head restraints

Head restraints are provided

for all seats.

WARNING

■Head restraint precautions

Observe the following precautions

regarding the head restraints.

Failure to do so may result in

death or serious injury.

Use the head restraints

designed for each respective

seat.

Adjust the head restraints to th ...

Fuel

Service data

Torque specification

Emission control

Service data

...

Wireless remote control

(if equipped)

The keys are equipped with the

following wireless remote control:

Vehicles without a smart key

system

Locks the doors

Unlocks the doors

Opens the windows*1 and

moon roof*1, 2

Opens the trunk

Sounds the alarm

Vehicles with a smart key system

Locks the doors

Unlocks the doors

Opens the ...