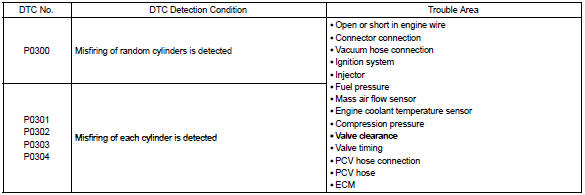

Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Random/multiple cylinder misfire

detected / Circuit description

Toyota Corolla (E120): Circuit description

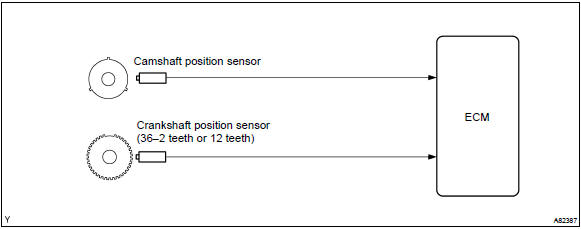

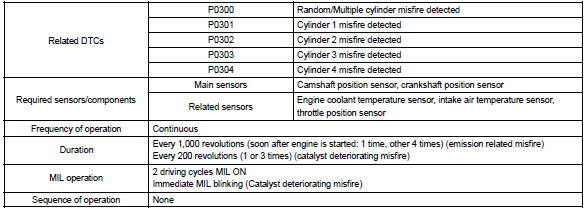

When a misfire occurs in the engine, hydrocarbons (hc) enter the exhaust in high concentrations. If this hc concentration is high enough, there could be an increase in exhaust emissions levels. High concentrations of hc passing through the catalyst also cause to temperature of the catalyst to increase, possibly damaging the catalyst. To prevent this increase in the emissions and limit the possibility of thermal damage, the ecm monitors the misfire rate. When the temperature of the catalyst reaches a point of thermal degradation, the ecm will blink the mil. For monitoring misfire, the ecm uses both the camshaft position sensor and crankshaft position sensor. The camshaft position sensor is used to identify misfiring cylinders and the crankshaft position sensor is used to measure variations in the crankshaft rotation speed. The misfire counter increments when crankshaft rotation speed variations exceed threshold values.

The ecm illuminates the mil if the misfiring rate exceeds a threshold value and could cause emissions deterioration.

Hint

: when codes for a misfiring cylinder are recorded repeatedly but no random misfire code is recorded, it indicates that the misfires have been detected and recorded at different times.

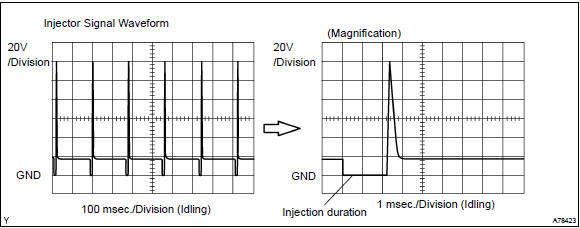

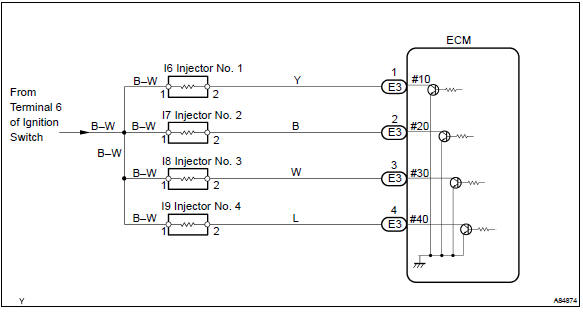

Reference: inspection using oscilloscope with the engine idling, check the waveform between terminals #10 to #40 and e01 of the ecm connectors.

Hint

: the correct waveform is as shown.

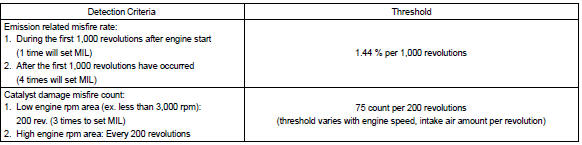

Monitor description

The ecm illuminates the mil if the misfiring rate exceeds a threshold value and could cause emissions deterioration.

The ecm will illuminate the mil when the percent misfire exceeds the specified limit per 1,000 engine revolutions.

One occurrence of excessive misfire during engine start will set the mil. Four occurrences are required to set the mil 1,000 revolutions after engine start. (2 Trip detection logic) the mil blinks when ”percent misfire causing catalyst damage” per 200 revolution met 3 times (1 time if the engine rpm is in high speed range). (Mil blinks immediately)

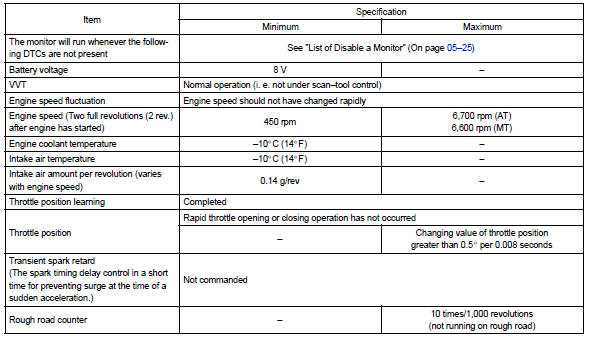

Monitor strategy

Typical enabling conditions

Typical malfunction thresholds

Wiring diagram

Refer to dtc p0351 for the wiring diagram of the ignition system.

Other materials:

Inspection procedure

Hint:

start the inspection from step 1 in case of using the hand–held tester and start

from step 2 in case of not

using hand–held tester.

1 Inspect brake actuator assy

Select the datalist mode on the hand–held tester.

check the operation sound of the abs pump motor when operat ...

Precaution

1. Work precautions

(A) vehicle protection

(1) when welding, cover glass, seats, carpets, etc. With

heat resistant fireploof covers to protect them.

(B) safety

(1) never stand in the path of the chain when using a puller

on the body or frame, and be sure to attach a safety

cable.

...

Basic repair hint

(A) hints on operations

1

Looks

Always wear a clean uniform.

Hat and safety shoes must be worn.

2

Vehicle protection

Set a grill cover, fender cover, seat cover and floor mat before

starting the operation.

3

Safe ...