Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Oxygen sensor circuit malfunction / Circuit description

Toyota Corolla (E120): Circuit description

Refer to dtc p0130

|

Dtc no |

Dtc detection condition |

Trouble area |

| P0136 | The following condition (a) or (b) continues for 300 seconds or

more:

|

|

Hint

: sensor 2 refers to the sensor farthest away from the engine assembly.

Monitor description

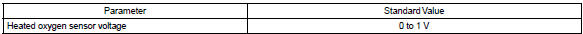

The heated oxygen sensor generates waveform of a voltage between 0 v and 1 v in response to the oxygen concentration in the exhaust gases. When the output voltage of the heated oxygen sensor is 0.5 V or more, the ecm judges that the air–fuel ratio is rich. When it is 0.40 V or less, the ecm judges that the air–fuel ratio is lean.

If the rear heated oxygen sensor output dose not change between rich and lean during ”stop and go” driving, the ecm interprets this as a malfunction in the rear heated oxygen sensor and sets a dtc. Also, if the sensor output remains at less than 0.05 V for more than 156 seconds when ecm monitored the heated oxygen sensor for 260 seconds while the air fuel feedback is being performed (the detecting condition differs depending on the type of vehicles), the ecm will interpret this as a fault. In either case, the ecm will turn on the mil and set a dtc.

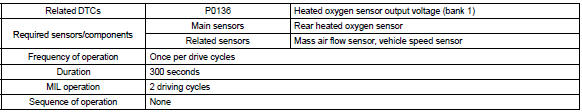

Monitor strategy

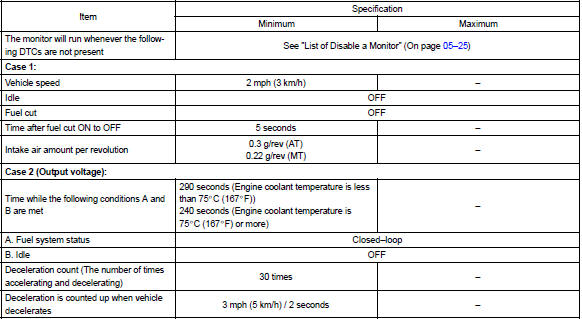

Typical enabling conditions

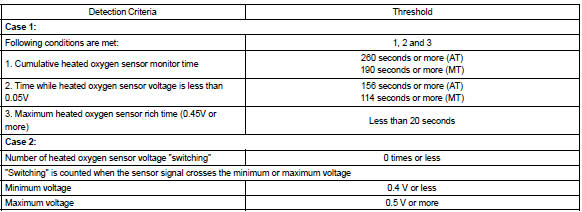

Typical malfunction thresholds

Component operating range

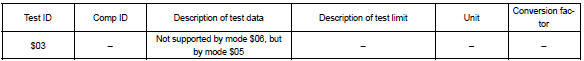

Monitor result (mode 06 data)

Refer to page 05–27 for detailed information on checking monitor status.

Wiring diagram

Refer to dtc p0130

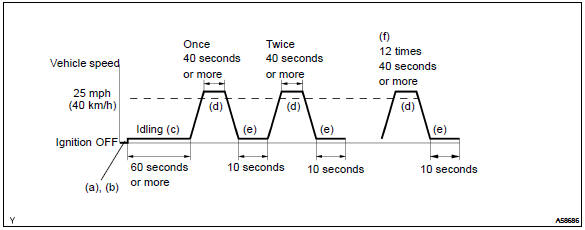

Confirmation driving pattern

- Connect the hand–held tester to the dlc3.

- switch the hand–held tester from the normal mode to the check mode .

- start the engine and let it idle for 60 seconds or more.

- drive the vehicle at 25 mph (40 km/h) or more for 40 seconds or more.

- let the engine idle for 10 seconds or more.

- perform steps (d) and (e) 12 times.

Hint

: if a malfunction exists, the mil will be illuminated on the multi information display during step (f).

Notice

: if the conditions in this test are not strictly followed, a malfunction detection will not occur. If you do not have a hand–held tester, turn the ignition switch off after performing steps from (c) to (f), then perform steps from (c) to (f) again.

Other materials:

Inspection procedure

1 Input signal check

See input signal check on page 05–745.

check indicator light operation when driving with vehicle

speed above 40 km/h (25 mph), and with vehicle speed

below 40 km/h (25 mph).

Ok:

vehicle speed above 40 km/h (25 mph):

indicator light blinks

vehicle speed be ...

If your vehicle overheats

The following may indicate that your vehicle is overheating.

● Vehicles without a multi-information display: The high engine coolant temperature

warning light comes on or a loss of power is experienced.

Vehicles with a multi-information display: The engine coolant temperature gauge&n ...

Switching the display

Press to display or hide the album

title.

If there is additional text, is

displayed.

Press and hold to display the remaining

text.

■USB memory functions

●Depending on the USB memory that is connected to the system, the device itself

may not be operable and certain function ...