Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Mass or volume air flow circuit

range/performance problem / Circuit description

Toyota Corolla (E120): Circuit description

Refer to dtcs p0100

|

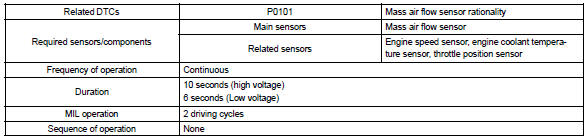

Dtc no. |

Dtc detection condition | Trouble area |

| P0101 | After engine is warmed up, conditions (a) to (d) continue for

more than 10 seconds (2 trip detection logic):

|

|

Conditions (a) and (b) continue for more than 6 seconds: (2 trip

detection logic)

|

Monitor description

The maf (mass air flow) sensor helps the ecm calculates the amount of air flowing through the throttle valve. The ecm uses this information to determine the fuel injection time and provides a proper air–fuel ratio.

Inside the maf sensor, there is a heated platinum wire exposed to the flow of intake air. By applying a specific current to the wire, the ecm heats this wire to a given temperature. The flow of incoming air cools the wire and an internal thermister, changing their resistance. To maintain a constant current value, the ecm varies the voltage applied to these components in the maf sensor. The voltage level is proportional to the air flow through the sensor and the ecm interprets this voltage as the intake air amount. If there is a defect in the sensor or an open or short circuit, the voltage level will deviate outside the normal operating range. The ecm interprets this deviation as a defect in the maf sensor and sets a dtc.

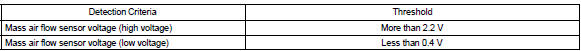

Example: if the voltage is more than 2.2 V at idle, or less than 0.4 V at idle off, the ecm interprets this as a defect in the maf sensor and sets a dtc.

Monitor strategy

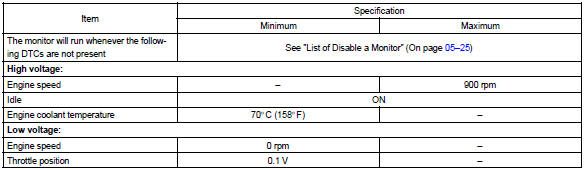

Typical enabling conditions

Typical malfunction thresholds

Wiring diagram

Refer to dtc p0100

Other materials:

License plate lamp assy

Replacement

1. Remove luggage compartment lock cylinder & key set

2. Remove luggage compartment door garnish outside

3. Remove license plate lamp assy

Pull the license plate light assy to the side of vehicle as

shown in the illustration and release the claw.

disconnect the c ...

Outside vehicle

General maintenance

Performing these maintenance checks on the vehicle in the owner’s

responsibility. The owner may

perform the maintenance or take the vehicle to a service center.

Check the parts of the vehicle described below on a daily basis. In most cases,

special tool are not

requir ...

Overhaul

Hint:

overhaul the rh side by the same procedure as the lh side.

1. Remove front wheel

2. Drain brake fluid

Notice:

wash the brake fluid off immediately if it comes into contact with any painted

surface.

3. Remove front disc brake cylinder sub–assy

Remove the union bolt and gasket ...