Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Camshaft position ”a” –timing over / Circuit description

Toyota Corolla (E120): Circuit description

Refer to dtc p0010

|

Dtc no. |

Dtc detection condition |

Trouble area |

| P0011 | Condition (a) or (b) continues after engine is warmed up and

engine speed at 550 to 4,000 rpm (problem of the advanced

ocv):

|

|

| P0012 | Condition (a) or (b) continues after engine is warmed up and

engine speed at 550 to 4,000 rpm (problem of the retarded

ocv):

|

Monitor description

The ecm optimizes the valve timing using the variable valve timing (vvt) system to control the intake valve camshaft. The vvt system includes the ecm, the oil control valve (ocv) and the vvt controller. The ecm sends a target ”duty–cycle” control signal to the ocv. This control signal, applied to the ocv, regulates the oil pressure supplied to the vvt controller. The vvt controller can advance or retard the intake valve camshaft.

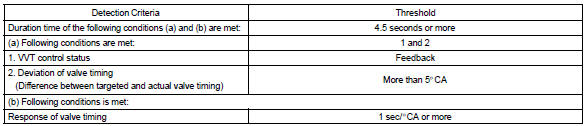

Example: when a difference between the targeted and actual valve timing is more than 5 camshaft angle ”ca” and this condition continues for more than 4.5 Sec, and if the ocv is forcibly activated 63 times or more.

Advanced cam dtcs are subject to ”1 trip” detection logic.

Retarded cam dtcs are subject to ”2 trip” detection logic.

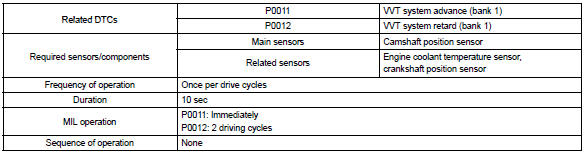

Monitor strategy

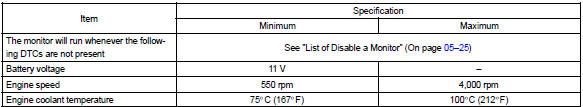

Typical enabling conditions

Typical malfunction thresholds

Wiring diagram

Refer to dtc p0010

Other materials:

Bluetooth® device registration status

1 Display the “Bluetooth* Setup” screen.

*: Bluetooth is a registered trademark of Bluetooth SIG, Inc.

2 Select the device.

3 Select “Device Info”.

4 Following screen is displayed:

1 Device Name

2 Change connection method

3 Bluetooth® Address

4 Display your telephone number

The n ...

Listening to an iPod

Connecting an iPod enables you to enjoy music from the vehicle speakers. Press

until “iPod” is displayed.

Connecting an iPod

Control panel

1 Power

2 Volume

3 Fast-forward or reverse

4 Repeat play

5 Shuffle playback

6 Select an iPod menu/song or display song list

7 Displays text mess ...

If your vehicle has to be stopped in an emergency

Only in an emergency, such as if it becomes impossible to stop the vehicle

in the normal way, stop the vehicle using the following procedure:

1 Steadily step on the brake pedal with both feet and firmly depress it.

Do not pump the brake pedal repeatedly as this will increase the effort required ...