Toyota Corolla (E120): Check and replace ecu

Notice

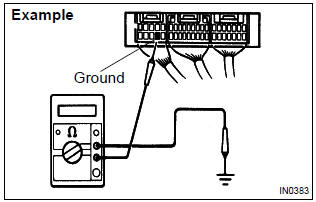

: start an inspection of the connector from the backside of the connector on the wire harness side with the connector connected to the ecu.

When no measurement condition is specified, perform the inspection with the engine stopped and also the ignition switch on.

- First check the ecu ground circuit. If it is faulty, repair it.

If it is normal, the ecu could be faulty. In this case, replace the ecu with one that functions normally and check if the symptoms appear.

- Measure the resistance between the ecu ground

terminal and body ground.

Resistance: 1 Ω or less

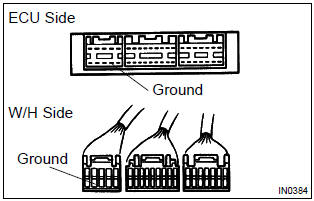

- Disconnect the ecu connector, check the ground terminals on the ecu side and wire harness side for bends and check the contact pressure.

Other materials:

Tire information

Typical tire symbols

► Full-size tire

► Compact spare tire

1 Tire size

2 DOT and Tire Identification Number (TIN)

3 Uniform tire quality grading

For details, see “Uniform Tire Quality Grading” that follows.

4 Location of treadwear indicators

5 Tire ply composition and ma ...

What to do if... (Troubleshooting)

If you have a problem, check the following before contacting your Toyota dealer.

The doors cannot be locked, unlocked, opened or closed

You lose your keys

● If you lose your keys or mechanical keys, new genuine keys or mechanical keys

can be made by your Toyota dealer.

● If you lo ...

Body

On–vehicle inspection

1. Canada:

tighten bolts and nuts on chassis and body

tighten the bolts and nuts on the chassis parts listed below, if

necessary

Front axle and suspension

drive train

rear axle and suspension

brake system

engine mounting

other chassis parts

...