Toyota Corolla (E120): Adjustment

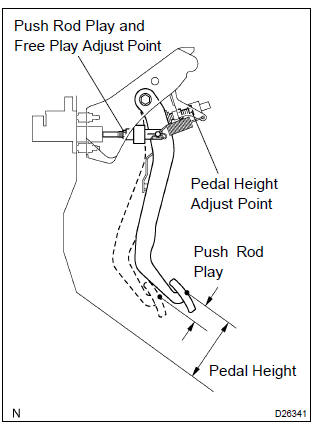

1. Inspect and adjust clutch pedal sub–assy

- Turn over the floor carpet.

- check that the pedal height is correct.

Pedal height from asphalt sheet: 135.8 – 145.8 Mm (5.346 – 5.740 In.)

- adjust the pedal height.

- Loosen the lock nut and turn the stopper bolt until

the height is correct. Tighten the lock nut.

Torque: 24.5 Nvm (245 Kgf·cm, 18 ft·lbf)

- check that the pedal free play and push rod play are correct.

- Depress the pedal until the clutch resistance begin

to be felt.

Pedal free play: 5.0 – 15.0 Mm (0.197 – 0591 In.)

- Gently depress the pedal until the resistance begins

to increase a little.

Push rod play at pedal top: 1.0 – 5.0 Mm (0.039 – 0.197 In.)

- Adjust the pedal free play and push rod play.

- Loosen the lock nut and turn the push rod until the free play and push rod play are correct.

- Tighten the lock nut.

- After adjusting the pedal free play, check the pedal height.

- Connect the air duct and install the lower finish panel.

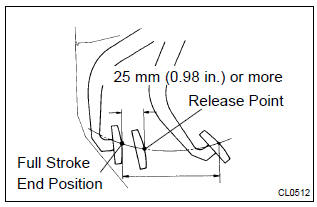

- Check the clutch release point.

- Pull the parking brake lever and install wheel stopper.

- Start the engine and idle the engine.

- Without depressing the clutch pedal, slowly shift the shift lever into reverse position until the gears contact.

- Gradually depress the clutch pedal and measure the stroke distance from the point that the gear noise stops (release point) up to the full stroke end position.

Standard distance: 25 mm (0.98 In.) Or more (from pedal stroke end position to release point) if the distance is not as specified, perform the following operations.

- Check pedal height.

- Check push rod play and pedal free play.

- Bleed the clutch line.

- Check the clutch cover assy and disc assy.

Other materials:

Taking out the spare tire

1 Remove the luggage floor cover.

2 Remove the tool tray.

3 Loosen the center fastener that secures the spare tire.

CAUTION

■When storing the spare tire

Be careful not to catch fingers or other body parts between the spare tire and

the body of the vehicle. ...

What to do if... (Troubleshooting)

If there is a problem with the hands-free system or a Bluetooth® device, first

check the table below.

► When using the hands-free system with a

Bluetooth® device

► When registering/connecting a cellular

phone

► When making/receiving a call

► When using the p ...

Tire size

■ Typical tire size information

The illustration indicates typical tire size.

1 Tire use (P = Passenger car, T = Temporary use)

2 Section width (millimeters)

3 Aspect ratio (tire height to section width)

4 Tire construction code (R = Radial, D = Diagonal)

5 Wheel diameter (inches)

6 Loa ...