Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Stop light switch circuit / Inspection procedure

Toyota Corolla (E120): Inspection procedure

Hand–held tester:

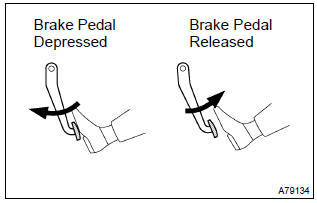

1 Check operation of stop light

- Check if the stop lights go on and off normally when the brake pedal is depressed and released.

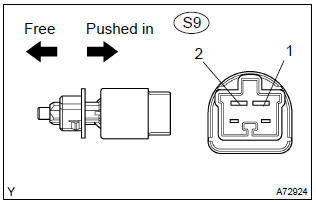

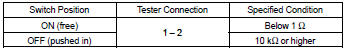

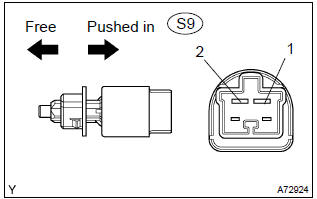

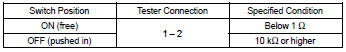

2 Inspect stop light switch assy

- Check the resistance between the terminals when the switch is turned on and off.

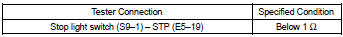

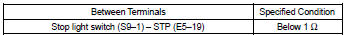

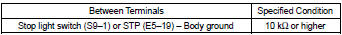

Standard:

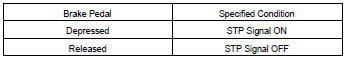

3 Read value of hand–held tester(stp signal)

- Turn the ignition switch on.

- select the item ”diagnosis / enhanced obd ii / data list / all / stop light sw” and read its value displayed on the hand–held tester.

Standard:

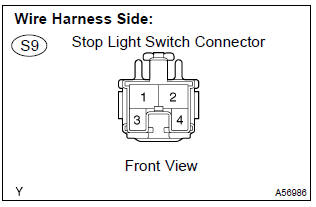

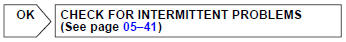

4 Check harness and connector(stop light switch – ecm)

- Disconnect the s9 stop light switch connector.

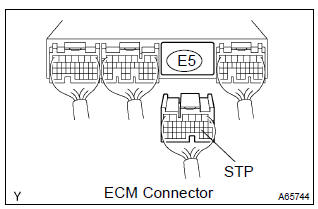

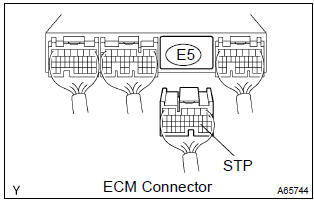

- disconnect the e5 ecm connector.

- check the resistance between the wire harness side connectors.

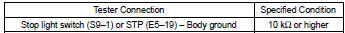

Standard (check for open):

Standard (check for short):

- Reconnect the ecm connector.

- reconnect the stop light switch connector.

Replace ecm

Obd ii scan tool (excluding hand–held tester):

1 Check operation of stop light

- Check if the stop lights go on and off normally when the brake pedal is depressed and released.

2 Inspect stop light switch assy

- Check the resistance between terminals when the switch on and off.

Standard:

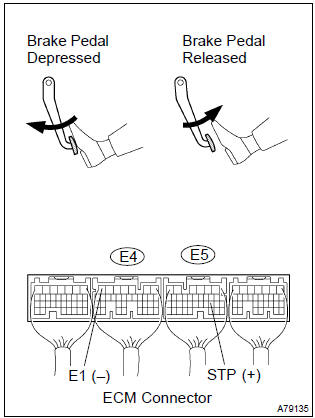

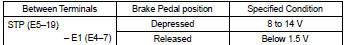

3 Inspect ecm(stp voltage)

- Turn the ignition switch on.

- measure the voltage between the terminals of the e4 and e5 ecm connectors.

Standard:

4 Check harness and connector(stop light switch – ecm)

- Disconnect the s9 stop light switch connector.

- disconnect the e5 ecm connector.

- check the resistance between the wire harness side connectors.

Standard (check for open):

Standard (check for short):

- Reconnect the ecm connector.

- reconnect the stop light switch connector.

Replace ecm

Other materials:

Circuit description

1 Check p squib circuit(airbag sensor assy center – instrument

panel passenger airbag assy)

Disconnect the negative (–) terminal cable from the battery,

and wait at least for 90 seconds.

disconnect the connectors between the airbag sensor

assy center and the instrument panel ...

Overhaul

Notice:

when using a vise, do not over tighten.

When installing, coat the parts indicated by the arrows with power

steering fluid .

1. Remove front wheel rh

2. Drain power steering fluid

3. Remove engine under cover rh

4. Remove fan and generator v belt

5. Disconnect oil reservoir to ...

Starting off on a steep uphill

► Automatic transmission or continuously

variable transmission

1 Make sure that the parking brake is set and shift the shift lever to D.

2 Gently depress the accelerator pedal.

3 Release the parking brake.

► Manual transmission

1 With the parking brake firmly set and the clutch pe ...