Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Throttle/pedal position

sensor/switch ”a” circuit / Inspection procedure

Toyota Corolla (E120): Inspection procedure

Hint

:

- if different dtcs related to different systems that have terminal e2 as the ground terminal are output simultaneously, terminal e2 may be open.

- Read freeze frame data using the hand-held tester or the obd ii scan tool. Freeze frame data records the engine conditions when a malfunction is detected. When troubleshooting, it is useful for determining whether the vehicle was running or stopped, the engine was warmed up or not, the air–fuel ratio was lean or rich, etc. At the time of the malfunction.

Hand–held tester:

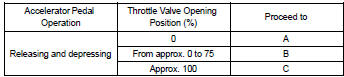

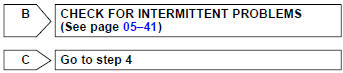

1 Read value of hand–held tester(throttle valve opening percentage)

- Connect the hand–held tester to the dlc3.

- turn the ignition switch on.

- select the item ”diagnosis / enhanced obd ii / data list / etcs / throttle pos” and read its value displayed on the hand–held tester.

Result:

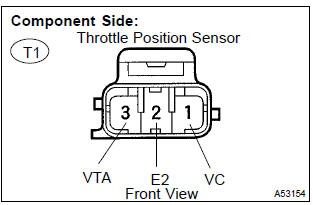

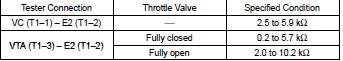

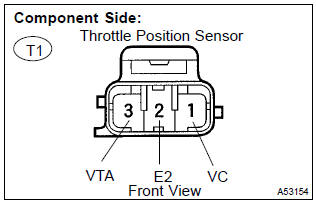

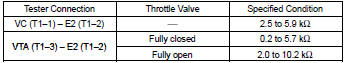

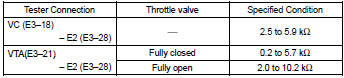

2 Inspect throttle position sensor

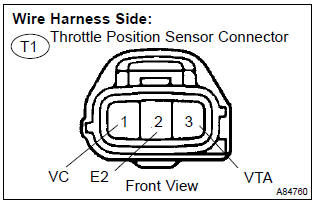

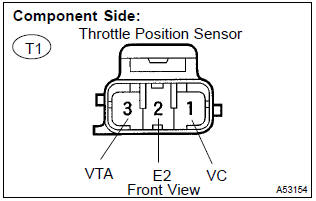

- Disconnect the t1 throttle position sensor connector.

- measure the resistance between the terminals of the throttle position sensor.

Standard

- Reconnect the throttle position sensor connector.

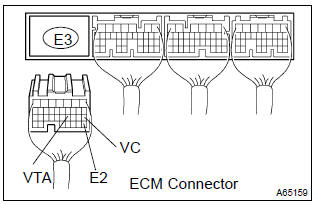

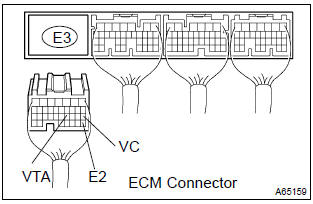

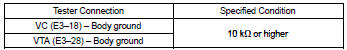

3 Check harness and connector(ecm – throttle position sensor)

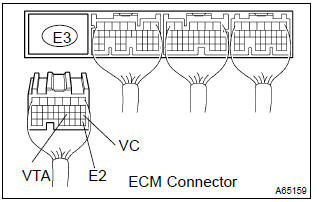

- Disconnect the e3 ecm connector.

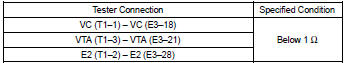

- measure the resistance between the terminals of the e3 ecm connector.

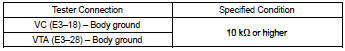

Standard:

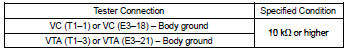

- Check the resistance between the terminals of the e3 ecm connector.

Standard (check for short):

- Reconnect the ecm connector.

Replace ecm

4 Inspect throttle position sensor

- Disconnect the t1 throttle position sensor connector.

- measure the resistance between the terminals of the throttle position sensor.

Standard:

- Reconnect the throttle position sensor connector.

5 Check harness and connector(ecm – throttle position sensor)

- Disconnect the e3 ecm connector.

- disconnect the t1 throttle position sensor connector.

- check the resistance between the wire harness side connectors.

Standard (check for open):

Standard (check for short):

- Reconnect the throttle position sensor connector.

- reconnect the ecm connector.

Replace ecm

Obd ii scan tool (excluding hand–held tester):

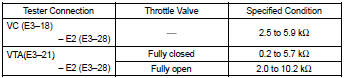

1 Inspect throttle position sensor

- Disconnect the t1 throttle position sensor connector.

- measure the resistance between the terminals of the throttle position sensor.

Standard:

- Reconnect the throttle position sensor connector.

2 Check harness and connector(throttle position sensor – ecm)

- Disconnect the e3 ecm connector.

- measure the resistance between the terminals of the e3 ecm connector.

Standard:

- Check the resistance between the terminals of the e3 ecm connector.

Standard (check for short):

- Reconnect the ecm connector.

Other materials:

Replacement

1. Remove console box sub–assy rear

2. Remove parking brake lever sub–assy

Disconnect the parking brake switch connector from the

parking brake switch.

remove the lock nut and adjusting nut from the parking

brake cable assy no.1.

Remove the 2 bolts.

Usin ...

Circuit description

Refer to dtc p0010

Dtc no.

Dtc detection condition

Trouble area

P0011

Condition (a) or (b) continues after engine is warmed up and

engine speed at 550 to 4,000 rpm (problem of the advanced

ocv):

valve timing does not change from current valve tim ...

Inspection procedure

Hint:

perform the troubleshooting of dtc p0335 first. If no trouble is

found, troubleshoot the engine mechanical

systems.

Read freeze frame data using the hand-held tester or the obd ii scan tool.

Freeze frame data records

the engine conditions when a malfunction is detected. When tr ...