Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Throttle/pedal position

sensor/switch ”a” circuit / Circuit description

Toyota Corolla (E120): Circuit description

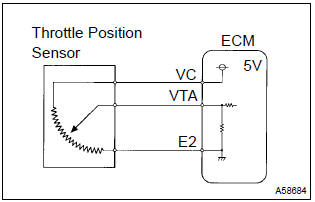

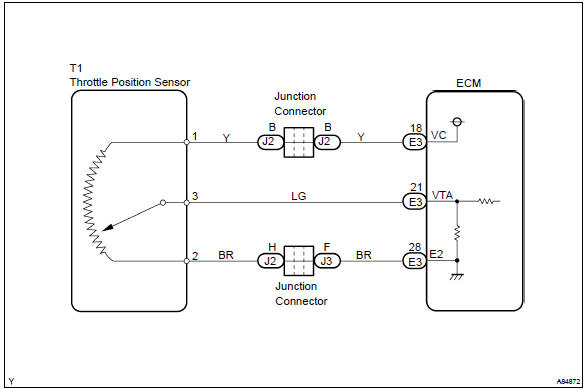

The throttle position sensor is mounted in the throttle body and detects the throttle valve opening angle.

When the throttle valve is fully closed, a voltage of approximately 0.3 To 1.0 V is applied to terminal vta of the ecm. The voltage applied to terminal vta of the ecm increases in proportion to the opening angle of the throttle valve and becomes approximately 3.2 To 4.9 V when the throttle valve is fully opened. The ecm judges the vehicle driving conditions from these signals input from terminal vta, uses them as one of the conditions for deciding the air–fuel ratio correction, power increase correction and fuel–cut control etc.

Hint

: after confirming dtcs, confirm the throttle valve opening percentage and closed throttle position switch condition using the hand–held tester or the obd ii scan tool.

Monitor description

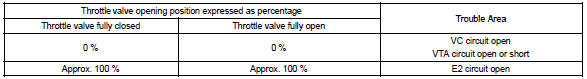

The throttle position sensor varies its resistance with the throttle valve angle. The ecm applies a regulated reference voltage to the throttle position sensor “+: vc” terminal and calculates the angle of the throttle valve based on the voltage present at the throttle position sensor “signal: vta” terminal.

When the throttle valve is near the fully closed position, the output voltage of the throttle position sensor is low. When it is near the fully open position, the output voltage is high.

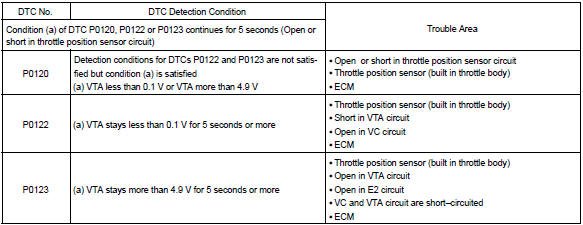

If the ecm detects that the output voltage of the throttle position sensor is out of the normal range, the ecm interprets this as a malfunction in the throttle position sensor and sets a dtc.

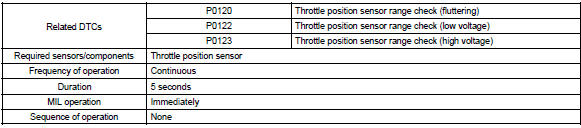

Monitor strategy

Typical enabling condition

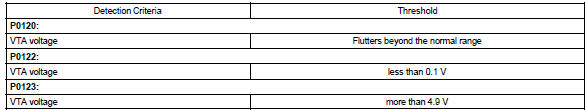

Typical malfunction thresholds

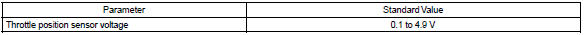

Component operating range

Wiring diagram

Other materials:

Replacement

Hint:

installation is in the reverse order of the removal. But the installation is

indicated only when it has a point.

1. Remove luggage compartment door cover

2. Remove rear spoiler

remove the 2 screws.

disconnect the wire harness connector.

put protective tape.

&nb ...

Inspection procedure

Hint:

this dtc chart is on the premise that the engine is cranked normally.

If the engine is not cranked, proceed

to the problem symptoms table on page 05–42.

Read freeze frame data using the hand-held tester or the obd ii scan

tool. Freeze frame data records

the engine conditions ...

Cruise control

Preparation

Sst

Recomended tools

Equipment

...