Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Camshaft position ”a” –timing over / Circuit description

Toyota Corolla (E120): Circuit description

Refer to dtc p0010

|

Dtc no. |

Dtc detection condition |

Trouble area |

| P0011 | Condition (a) or (b) continues after engine is warmed up and

engine speed at 550 to 4,000 rpm (problem of the advanced

ocv):

|

|

| P0012 | Condition (a) or (b) continues after engine is warmed up and

engine speed at 550 to 4,000 rpm (problem of the retarded

ocv):

|

Monitor description

The ecm optimizes the valve timing using the variable valve timing (vvt) system to control the intake valve camshaft. The vvt system includes the ecm, the oil control valve (ocv) and the vvt controller. The ecm sends a target ”duty–cycle” control signal to the ocv. This control signal, applied to the ocv, regulates the oil pressure supplied to the vvt controller. The vvt controller can advance or retard the intake valve camshaft.

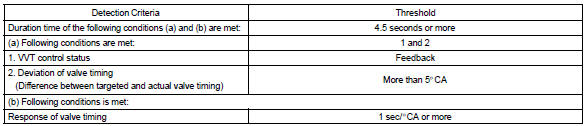

Example: when a difference between the targeted and actual valve timing is more than 5 camshaft angle ”ca” and this condition continues for more than 4.5 Sec, and if the ocv is forcibly activated 63 times or more.

Advanced cam dtcs are subject to ”1 trip” detection logic.

Retarded cam dtcs are subject to ”2 trip” detection logic.

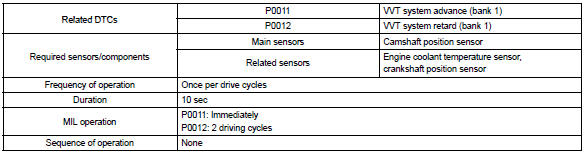

Monitor strategy

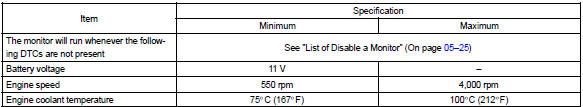

Typical enabling conditions

Typical malfunction thresholds

Wiring diagram

Refer to dtc p0010

Other materials:

Circuit description

The p/t squib (rh) circuit consists of the airbag sensor assy center and seat

belt pretensioner (rh).

It causes the srs to deploy when the srs deployment conditions are satisfied.

Dtc b0130/63 is recorded when a short is detected in the p/t squib (rh) circuit.

Wiring diagram

...

Inspection procedure

1 Check d squib circuit(airbag sensor assy center – horn button

assy)

Disconnect the negative (–) terminal cable from the battery,

and wait at least for 90 seconds.

disconnect the connectors between the airbag sensor

assy center and the horn button assy.

connect the ...

Replacement

1. Remove engine under cover rh

2. Drain coolant

3. Remove front wheel rh

4. Remove cylinder head cover no.2

Remove the 2 nuts, 2 clips and cylinder head cover.

5. Remove fan and generator v belt

Turn the v–ribbed belt tensioner slowly clockwise and

loosen it. Then, remove ...