Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Supplemental restraint system / Short in d squib circuit (to b+) / Inspection procedure

Toyota Corolla (E120): Inspection procedure

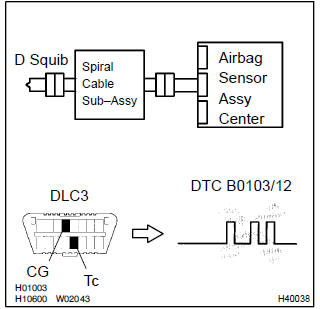

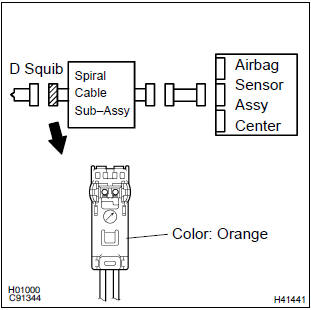

1 Check d squib circuit(airbag sensor assy center – horn button assy)

- Disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- disconnect the connectors between the airbag sensor assy center and the horn button assy.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on.

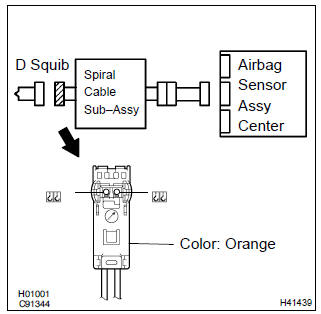

- for the orange connector (on the spiral cable sub–assy

side) between the horn button assy and the spiral cable

sub–assy, measure the voltage between d+ and body

ground.

Ok: voltage: below 1 v

2 Check air bag sensor assy center

- Turn the ignition switch to lock.

- disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- connect the connector to the airbag sensor assy center.

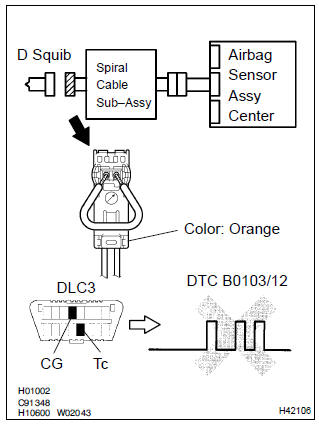

- using a service wire, connect d+ and d– of the orange connector (on the spiral cable sub–assy side) between the horn button assy and the spiral cable sub–assy.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 60 seconds.

- check the dtc .

Ok: dtc b0103/12 is not output.

Hint

: codes other than code b0103/12 may be output at this time, but they are not relevant to this check.

3 Check d squib

Sst 09843–18040

- Turn the ignition switch to lock.

- disconnect the negative (–) terminal cable from the battery, and wait at least for 90 seconds.

- connect the horn button assy connectors.

- connect the negative (–) terminal cable to the battery, and wait at least for 2 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- clear the dtc stored in memory .

- turn the ignition switch to lock, and wait at least for 20 seconds.

- turn the ignition switch to on, and wait at least for 20 seconds.

- check the dtc .

Ok: dtc b0103/12 is not output.

Hint

: codes other than code b0103/12 may be output at this time, but they are not relevant to this check.

4 Use simulation method to check

Replace all srs components including the wire harness

5 Check instrument panel wire(airbag sensor assy center – spiral cable sub–assy)

- Turn the ignition switch to lock.

- disconnect the connectors of the instrument panel wire.

- turn the ignition switch to on.

- for the connector (on the spiral cable sub–assy side) between

the airbag sensor assy center and the spiral cable

sub–assy, measure the voltage between d+ and body

ground.

Ok: voltage: below 1 v

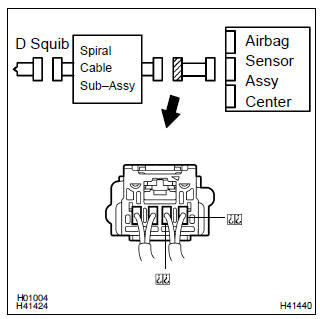

6 Check spiral cable sub–assy

- For the orange connector (on the spiral cable sub–assy

side) between the horn button assy and the spiral cable

sub–assy, measure the voltage between d+ and body

ground.

Ok: voltage: below 1 v

7 Use simulation method to check

Replace all srs components including the wire harness

Other materials:

Inspection procedure

1 Check p/t squib(rh) circuit(airbag sensor assy center – front

seat outer belt assy rh)

Disconnect the negative (–) terminal cable from the battery,

and wait at least for 90 seconds.

disconnect the connectors between the airbag sensor

assy center and the seat belt pretensio ...

Circuit description

The airbag sensor front lh circuit consists of the airbag sensor assy center

and airbag sensor front lh.

Dtc b1158/b1159/16 is recorded when malfunction is detected in the airbag sensor

front lh circuit.

Wiring diagram

...

Replacement

1. Remove radiator grille sub–assy

2. Remove front bumper cover

3. Remove fog lamp assy lh

Remove a nut and release a claw.

remove the fog light assy lh.

4. Put vehicle these conditions

5. Adjust fog light aim

6. Check fog light aim ...