Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Crankshaft position sensor ”a”

circuit / Inspection procedure

Toyota Corolla (E120): Inspection procedure

Hint

:

- perform the troubleshooting of dtc p0335 first. If no trouble is

found, troubleshoot the engine mechanical

systems.

Read freeze frame data using the hand-held tester or the obd ii scan tool. Freeze frame data records the engine conditions when a malfunction is detected. When troubleshooting, it is useful for determining whether the vehicle was running or stopped, the engine was warmed up or not, the air–fuel ratio was lean or rich, etc. At the time of the malfunction.

- Read value of hand–held tester or obd ii scan tool

(a) connect the hand–held tester or the obd ii scan tool to the dlc3.

(B) start the engine and push the hand–held tester or the obd ii scan tool main switch on.

(C) select the item ”diagnosis / enhanced obd ii / data list / all / engine spd”.

- The engine speed can be confirmed in data list using the hand–held tester or obd ii scan tool. If there is no ne signals from the crankshaft position sensor despite the engine revolving, the engine speed will be indicated as zero. If voltage output of the crankshaft position sensor is insufficient, the engine speed will be indicated as lower prm (than the actual rpm).

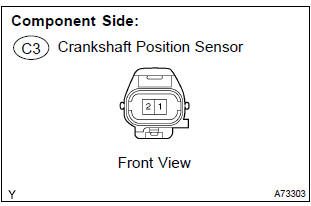

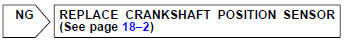

1 Inspect crankshaft position sensor(resistance)

- Disconnect the c43crankshaft position sensor connector.

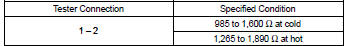

- measure the resistance between the terminals of the crankshaft position sensor connector.

Standaed:

Notice

: ”cold” and ”hot” shown above mean the temperature of the coils themselves. ”Cold” is from –10 c (14 f) to 50 c (122 f) and ”hot” is from 50 c (122 f) to 100 c (212 f).

- reconnect the crankshaft position sensor connector.

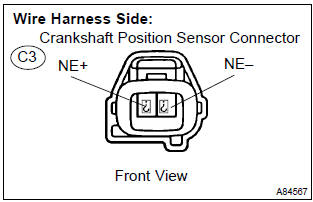

2 Check harness and connector(crankshaft position sensor – ecm)

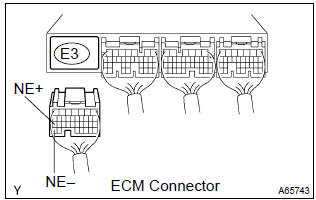

- Disconnect the c3 crankshaft position sensor connector.

- disconnect the e3 ecm connector.

- check the resistance between the wire harness side connectors.

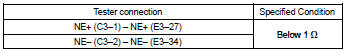

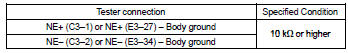

Standard (check for open):

Standard (check for short):

- Reconnect the ecm connector.

- reconnect the crankshaft position sensor connector.

3 Check sensor installation(crankshaft position sensor)

- Check the crankshaft position sensor installation .

4 Check crankshaft position sensor plate(teeth of sensor plate(crankshaft))

- Check the teeth of the sensor plate.

Replace ecm

Other materials:

Basic inspection

When the malfunction is not confirmed in the dtc check, troubleshooting

should be carried out in all the

possible circuits considered as causes of the problem. In many cases, by

carrying out the basic engine check

shown in the following flowchart, the location causing the problem can be found ...

Glossary of tire terminology

*: Table 1 - Occupant loading and distribution for vehicle normal load for various

designated seating capacities

...

On–vehicle inspection

Notice:

”cold” and ”hot” in these sentences express the temperature of the coils

themselves. ”Cold” is from

–10 c (14 f) to 50 c (122 f) and ”hot” is from 50 c (122 f) to 100 c (212 f).

1. Inspect ignition coil (with igniter) and spark test

confirm dtc.

Notice:

...