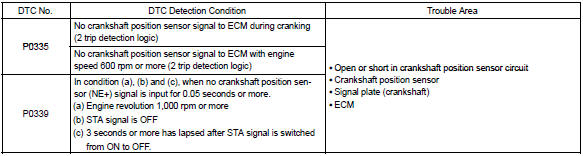

Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Crankshaft position sensor ”a”

circuit / Circuit description

Toyota Corolla (E120): Circuit description

The crankshaft position sensor (ne signal) consists of a magnet, iron core and pickup coil.

The ne signal plate (crankshaft position sensor plate) has 34 teeth and is installed on the crankshaft. The ne signal sensor generates 34 signals for each engine revolution. This sensor monitors a plate (timing rotor) located on the crankshaft timing pulley and is used by the ecm to detect crankshaft angle and engine speed (rpm/ne). As the crankshaft timing pulley rotates through an engine revolution, this sensor communicates the rotation of the ne signal plate as a pulse signal to the ecm. Based on the signal, the ecm controls fuel injection time and ignition timing.

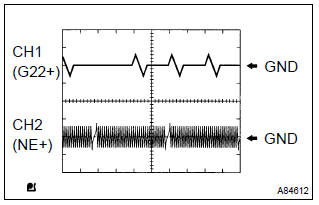

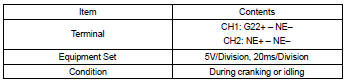

Reference: inspection using the oscilloscope.

Hint

: the correct waveform is as shown on the left.

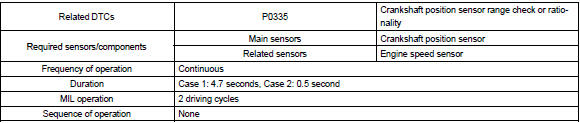

Monitor description

If there is no signal from the crankshaft sensor despite the engine revolving, the ecm interprets this as a malfunction of the sensor.

Monitor strategy

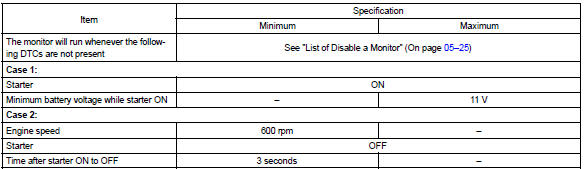

Typical enabling conditions

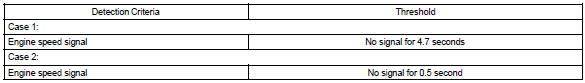

Typical malfunction thresholds

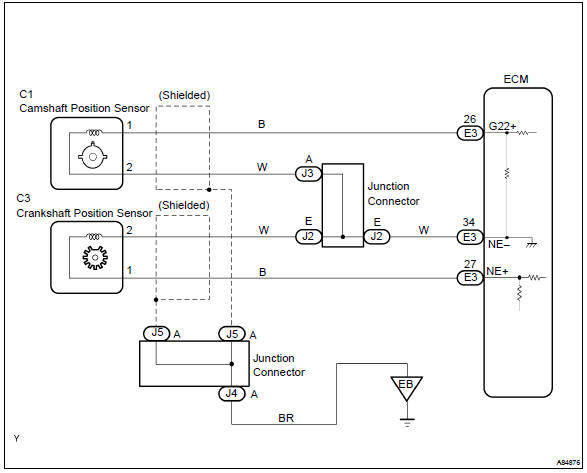

Wiring diagram

Other materials:

Starting & charging

Preparation

Sst

Recomended tools

Equipment

...

Toyota Safety Sense 3.0 software

update

It is necessary to enter a

connected services contract,

provided by Toyota, to

use these functions. For

details, contact your Toyota

dealer.

WARNING

■For safe use

When the Toyota Safety Sense

3.0 software is updated, the operating

methods of functions may

change. Using this system without

knowing ...

The ambient temperature does not display

Wiring diagram

Inspection procedure

1 Inspect outer ambient temperature sensor

Remove cooler (ambient temp. Sensor) thermistor.

measure resistance between terminals 1 and 2 of cooler

(ambient temp. Sensor) thermistor connector at each temperature.

Resistance:

at 0 c (0 f) ...