Toyota Corolla (E120): Inspection

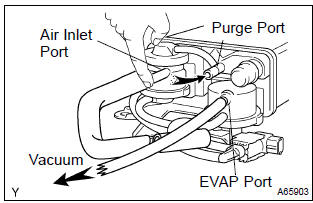

1. Charcoal canister assy

- Visually check the charcoal canister for cracks or damage.

- Inspect the charcoal canister operation.

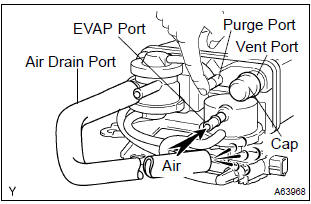

- Plug the vent port with the cap.

- While holding the purge port closed, blow air (1.76 Kpa, 18 gf/cm2, 0.26 Psi) into the evap port and check that air flows from the air drain port.

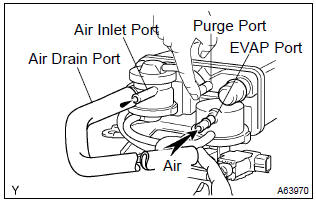

- While holding the purge port and the air drain port closed, blow air (1.76 Kpa, 18 gf/cm2, 0.26 Psi) into the evap port and check that air does not flow from the air inlet port.

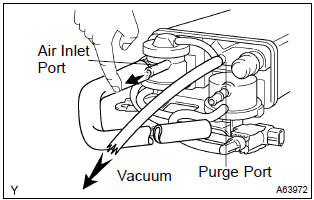

- Apply vaccum (3.43 Kpa, 25.7 Mmhg, 1.01 In.Hg) to the purge port, check that the vacuum dose not decrease when the air inlet port is closed, and check that the vacuum decreases when the air inlet port is released.

- While holding the air inlet port closed, apply vacuum

(3.43 Kpa, 25.7 Mmhg, 1.01 In.Hg) to the evap port

and check that air flows into the purge port.

If operation is not as spacified, replace the charcoal canister.

- Remove the hose and cap from vent port.

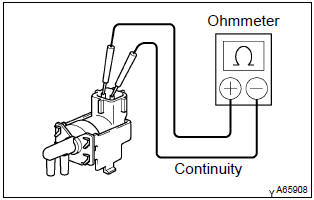

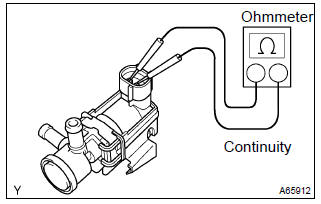

- Inspect vsv for pressure swiching valve

- using an ohmmeter, check that there is continuity

between the terminals.

Resistance: 37 – 44 w at 20 c (68 f) if there is no continuity, replace the vsv.

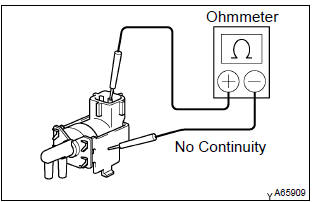

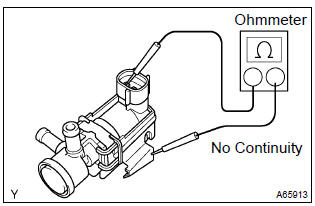

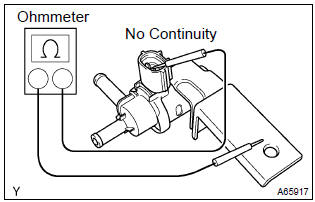

- Using an ohmmeter, check that there is no continuity

between each terminal and the body.

If there is continuity, replace the vsv.

- Check that air does not flow from ports e to f.

- Apply battery positive voltage across the terminals.

- Check that air flows from ports e to f.

If operation is not as specified, replace the vsv.

2. Ventilation valve sub–assy

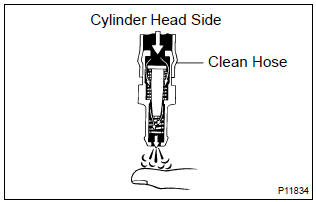

- Install clean hose to the pcv valve.

- inspect the pcv valve operation.

- Blow air into the cylinder head side, and check that air passes through easily.

Caution

: do not suck air through the valve. Petroleum substances inside the valve air harmful.

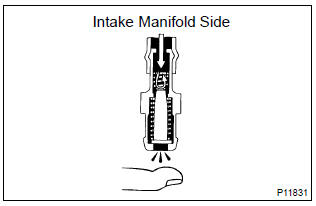

- Blow air into the intake manifold side, and check

that air passes through with difficulty.

If operation is not as specified, replace the pcv valve.

- remove clean hose from the pcv valve.

3. Fuel tank cap assy

- Visually check if cap and/or gasket are deformed or damaged.

If necessary, repair or replace the cap.

4. Vacuum switching valve no.1

- Inspect vsv for evaporative emission (evap).

- Using an ohmmeter, check that there is continuity

between the terminals.

Resistance: 27 – 33 Ω at 20 c (68 f) if there is no continuity, replace the vsv.

- Using an ohmmeter, check that there is no continuity

between each terminal and the body.

If there is continuity, replace the vsv.

- Check that air flows from ports e to f.

- Apply battery positive voltage across the terminals.

- Check that air does not flow from ports e to f.

If operation is not as specified, replace the vsv.

5. Vacuum switching valve assy no.1

- Inspect vsv for canister closed valve (ccv).

- Using an ohmmeter, check that there is continuity

between the terminals.

Resistance: 25 – 30 Ω at 20 c (68 f) if there is no continuity, replace the vsv.

- Using an ohmmeter, check that there is no continuity

between each terminal and the body.

If there is continuity, replace the vsv.

- Check that air flows from ports a to b.

- Apply battery positive voltage across the terminals.

- Check that air does not flow from ports a to b.

If operation is not as specified, replace the vsv.

Other materials:

Inspection

1. Cooler thermistor no.1

Check resistance between terminals 1 and 2 of cooler

thermistor no. 1 At each temperature, as shown in the

chart.

Resistance:

If resistance value is not as specified, replace the sensor.

2. Cooler and accessory assy

Inspect blower switch contin ...

Cd cannot be inserted or is ejected right after

insertion

Wiring diagram

Inspection procedure

1 Check if a proper cd is inserted

Check that a proper cd is inserted.

Make sure that the cd is normal audio cd, and that there is no

deformation, flaw, stain, burr and

other defects on the cd.

Standard: normal audio cd.

Reference:

...

Wireless remote control/electronic key battery

Replace the battery with a

new one if it is depleted.

As the key may be damaged

if the following procedure is

not performed properly, it is

recommended that key battery

replacement be performed

by your Toyota

dealer.

■If the key battery is depleted

The following symptoms may occur:

The smart ke ...