Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Idle air control System/ Circuit / Circuit description

Toyota Corolla (E120): Circuit description

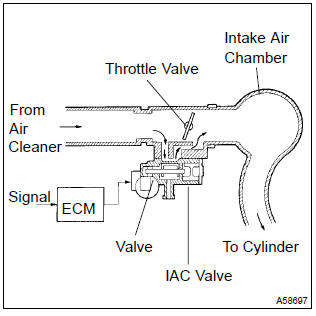

The rotary solenoid type idle air control (iac) valve is located under the throttle body and intake air bypassing the throttle valve flows into the iac valve through the passage.

In this way the intake air volume bypassing the throttle valve is regulated, controls the engine speed.

The ecm operates the iac valve only to perform idle–up and provide feedback for the target idling speed.

Monitor description

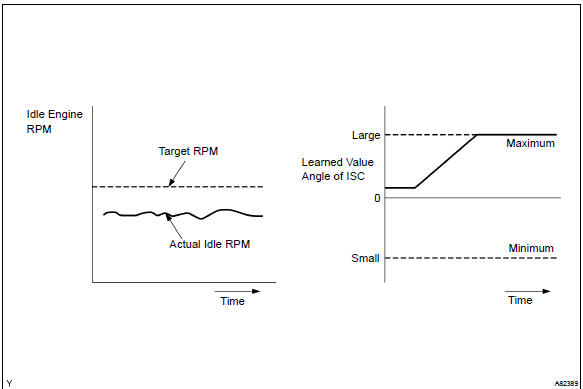

The idle speeds are determined depending on the volume of air that passes through the iac valve. When the volume is large, the idle speed becomes higher. When the volume is small, the idle speed becomes lower.

The iac valve controls the air volume that bypasses the throttle valve. The engine control module (ecm) sends duty signals to the iac valve and drives the iac valve stepper motor to determine the air volume that bypasses the throttle valve.

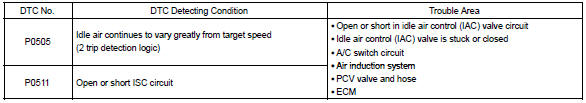

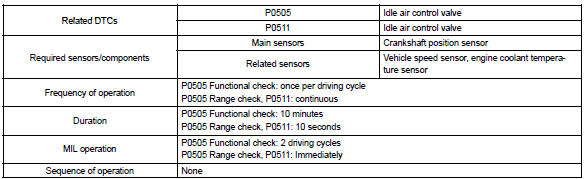

Although the ecm regulates the idle engine rpm with the feedback control in several vehicle stopped, actual idle rpm does not reach the targeted rpm and a learned valve angle of the idle air control (iac) remains at the maximum or remains at the minimum, the ecm determines to detect malfunction in the iac system.

Example: if the rpm difference between the targeted and actual idle engine rpms exceeds 200 rpm (*1) with the vehicle stopped in an idle, and this occurs 5 times, or if the learned value angle of the iac remains at its maximum or minimum angle for 5 seconds, p505 is detected.

P0511 is detected as an open/short circuit in the iac if the rate of duty signal input to the iac valve has stuck at 0 or 100 %.

*1: Threshold rpm is varied by an engine load.

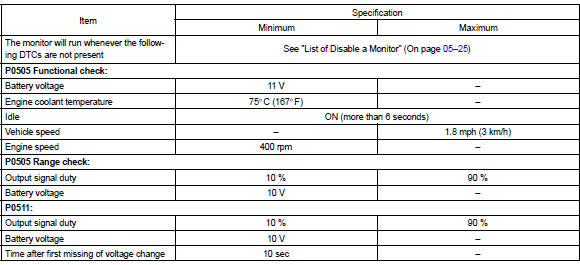

Monitor strategy

Typical enabling condition

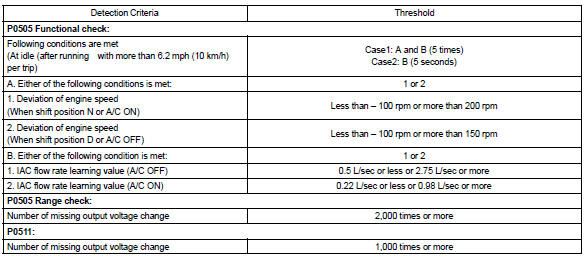

Typical malfunction thresholds

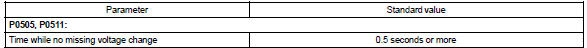

Component operating range

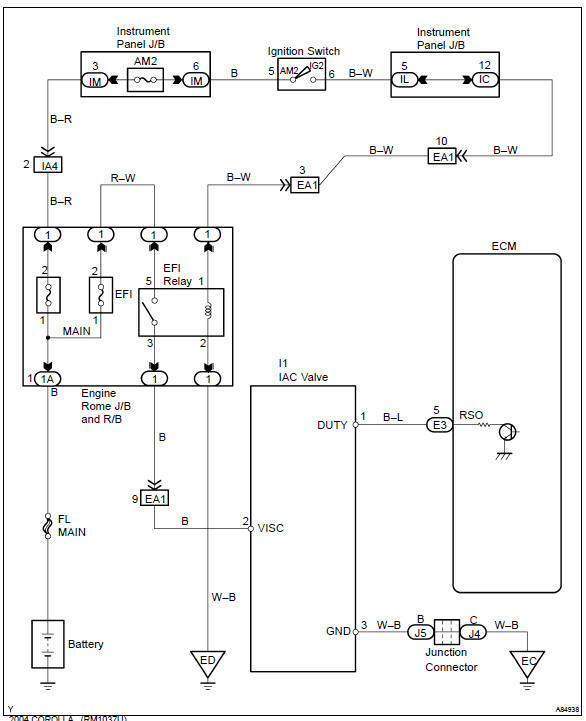

Wiring diagram

Other materials:

Power point socket assy

Replacement

Hint: components:

1. Remove floor shift shift lever knob sub–assy (m/t transaxle)

2. Remove console panel upper

3. Remove power point socket assy

Turn the socket in the circumference direction as shown

the illustration, disengage the claw between the socket

and the pow ...

Circuit description

Refer to dtc c0200/31, c0205/32, c1235/35, c1236/36

Hint:

Dtc no. C0210/33, c1238/38 is for the right rear speed sensor.

Dtc no. C0215/34, c1239/39 is for the left rear speed sensor.

Wiring diagram

...

Inspection procedure

Hint:

if dtc p0441 (purge flow), p0446 (vsv for ccv or vsv for pressure

switching valve), p0451, p0452

or p0453 is output with dtc p0442 or p0456 , first troubleshoot

dtc p0441, p0446, p0451, p0452 or p0453. If no malfunction is detected,

troubleshoot dtc

p0442 or p0456 next.

...