Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Sfi system / Readiness monitor drive pattern / Catalyst monitor (o2s type)

Toyota Corolla (E120): Catalyst monitor (o2s type)

- Preconditions

The monitor will not run unless:

- mil is off.

- Engine coolant temperature (ect) is 176°f (80 °C) or greater.

- Intake air temperature (iat) is 14°f (–10 °C) or greater.*

Notice

: * 2002 and later my vehicles: the readiness test can be completed in cold ambient conditions (less than 14°f / –10 °C), if the drive pattern is repeated a second time after cycling the ignition off.

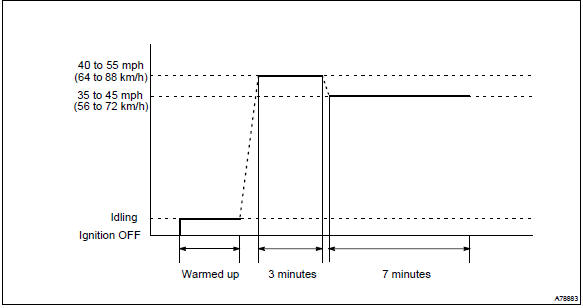

- Drive pattern

- connect the obd ii scan tool to the dlc3 to check monitor status and preconditions.

- Drive the vehicle at 40 to 55 mph (64 to 88 km/h) for approximately 3 minutes.

Notice

: drive with smooth throttle operation and avoid sudden acceleration.

If iat is less than 50°f (10 °C) when starting engine, continue to drive vehicle at 40 to 55 mph (64 to 88km/h) for approximately 4 minutes.

- Drive the vehicle at 35 to 45 mph (56 to 72 km/h) for approximately 7 minutes.

Notice

: drive with smooth throttle operation and avoid sudden deceleration as much as possible with the throttle fully closed.

- If readiness status dose not switch to complete, make sure that the preconditions are met and the ignition switch is turned off and then repeat steps (2) and (3).

- Release pressure in the fuel tank by removing and then reinstalling the fuel tank cap.

- Start the engine and immediately begin driving as directed.

Other materials:

If a warning message is displayed

The multi-information display

shows warnings for

system malfunctions and

incorrectly performed operations,

and messages that

indicate a need for maintenance.

When a message is

displayed, perform the

appropriate corrective

action for the message.

If a warning message is displayed

again after the

ap ...

Location of the storage features

Bottle holders/door pockets

Open trays (if equipped)

Glove box

Cup holders (if equipped)

Console box

WARNING

■Items that should not be left

in the storage spaces

Do not leave glasses,

spray cans in the storage spaces,

as this may cause the following

when cabin temperature becomes

high:

...

Odometer and trip meter

display

■ Changing the display

Press the display change button

until the desired item is displayed.

■ Display items

Odometer

Displays the total distance the vehicle

has been driven.

Trip meter A/Trip meter B

Displays the distance the vehicle

has been driven since the meter

was last reset. Trip me ...