Toyota Corolla (E120): Adjustment

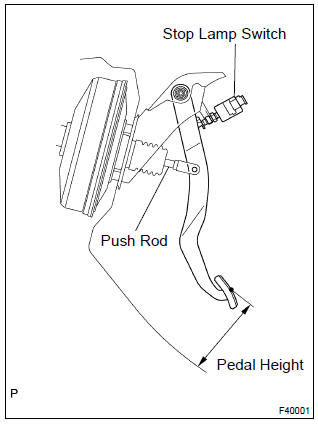

1. Check and adjust brake pedal height

- Inspect brake pedal height.

Pedal height from asphalt sheet: m/t: 134.9 – 144.9 Mm (5.311 – 5.703 In.) A/t: 136.0 – 146.0 Mm (5.353 – 5.747 In.)

- Disconnect the connector from the stop lamp switch.

- Remove the stop lamp switch.

- Loosen the clevis lock nut.

- Adjust the pedal height by turning the pedal push rod.

- Tighten the push rod lock nut.

Torque: 26 nvm (265 Kgf·cm, 19 ft·lbf)

- install the stop lamp switch.

- Connect the connector to the stop lamp switch.

- Push the brake pedal in 5 – 15 mm (0.20 – 0.59 In.), And turn the stop lamp switch to lock the nut in the position where the stop lamp goes off.

- After installation, push the brake pedal in 5 – 15 mm (0.20 – 0.59 In.), Check that stop lamp comes on.

2. Check pedal free play

- Stop the engine and depress the brake pedal several times until there is no more vacuum left in the booster.

- push in the pedal until the beginning of the resistance is

felt. Measure the distance, as shown in the installation.

Pedal free play: 1 – 6 mm (0.04 – 0.24 In.)

If incorrect, check the stop lamp switch clearance.

If the clearance is ok, then troubleshoot the brake system.

Stop lamp switch clearance: 0.5 – 2.4 Mm (0.020 – 0.094 In.)

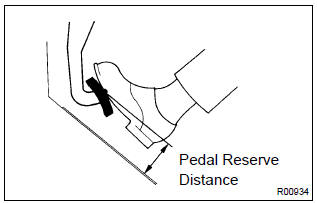

3. Check pedal reserve distance

- Release the parking brake lever.

With engine running, depress the pedal and measure the pedal reserve distance, as shown in the installation.

Pedal reserve distance from asphalt sheet at 490 n (50 kgf, 110.2 Lbf): more than 70 mm (2.76 In.)

If incorrect, troubleshoot the brake system.

Other materials:

Tire information

Typical tire symbols

► Full-size tire

► Compact spare tire

1 Tire size

2 DOT and Tire Identification Number (TIN)

3 Uniform tire quality grading

For details, see “Uniform Tire Quality Grading” that follows.

4 Location of treadwear indicators

5 Tire ply composition and ma ...

Checking and replacing fuses

If any of the electrical components

do not operate, a

fuse may have blown. If this

happens, check and replace

the fuses as necessary.

Checking and replacing

fuses

1. Turn the engine switch off.

2. Open the fuse box cover.

Engine compartment: type A

fuse box

Push the tabs in and lift the lid off.

E ...

Glossary of tire terminology

*: Table 1 - Occupant loading and distribution for vehicle normal load for various

designated seating capacities

...