Toyota Corolla (E120) 2002–2008 Repair Manual / Diagnostics / Audio system / Sound quality is bad in all modes (volume is too low)

Toyota Corolla (E120): Sound quality is bad in all modes (volume is too low)

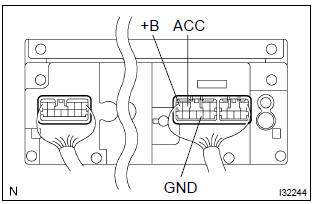

Wiring diagram

Inspection procedure

1 Adjust sound quality

- Adjust the sound quality.

- Operate the radio receiver assy to adjust the sound quality.

Standard: malfunction disappear.

2 Compare it with another car of same model

- Compare it with another vehicle of the same model.

- Compare with the vehicle of the same type which does not have a

trouble to see if there is any

difference in the condition of trouble occurrence.

Standard: no difference found.

3 Check harness and connector(between radio receiver assy and speaker)

4 Inspect front no.1 Speaker assy

- Preparation for check

- disconnect the connector of the speaker.

- resistance check

- check the resistance between the terminals of the speaker.

Notice

: the speaker should not be removed for checking.

Standard value: 4 Ω

5 Inspect front no.2 Speaker assy

- Check that malfunction disappear when a known good speaker is installed.

Standard: malfunction disappear.

Hint

: connect the all connectors of speakers.

6 Inspect rear speaker assy

- Preparation for check

- disconnect the connector of the speaker.

- resistance check

- check the resistance between the terminals of the speaker.

Notice

: the speaker should not be removed for checking.

Standard value: 6 Ω

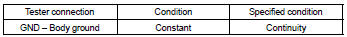

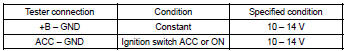

7 Inspect radio receiver assy(+b, acc, gnd)

- Check that the continuity between terminals at each condition, as shown in the chart.

Standard:

- Check that the voltage between terminals at each condition, as shown in the chart.

Standard:

Repair or replace harness or connector

Other materials:

If you have a flat tire

Your vehicle is equipped

with a spare tire. The flat tire

can be replaced with the

spare tire.

WARNING

■If you have a flat tire

Do not continue driving with a flat

tire. Driving even a short distance

with a flat tire can damage the tire

and the wheel beyond repair,

which could result in an acciden ...

Circuit description

Refer to dtc p0115

Dtc no.

Dtc detection condition

Trouble area

P0116

If engine coolant temperature (ect) was between 35 c (95 °F)

and 60 c (140 °F) when starting the engine, and also conditions

(a) and (b) are met:

vehicle has run with acceleration an ...

Wiring

Power source

Location

...