Toyota Corolla (E120): Inspection procedure

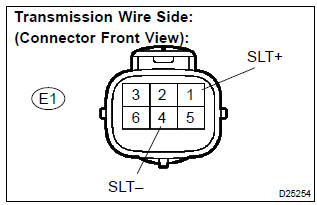

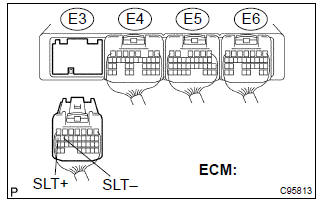

1 Inspect transmission wire(slt)

- Disconnect the transmission wire connector from the transaxle.

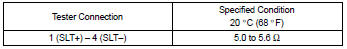

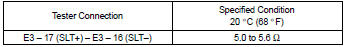

- measure the resistance according to the value(s) in the table below.

Standard:

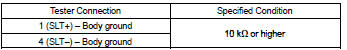

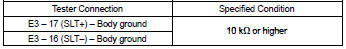

- Measure the resistance according to the value(s) in the

table below.

Standard (check for short):

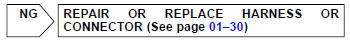

2 Check harness and connector(transmission wire – ecm)

- Connect the transmission wire connector to the transaxle.

- disconnect the ecm connector.

- measure the resistance according to the value(s) in the table below.

Standard:

- Measure the resistance according to the value(s) in the table below.

Standard (check for short):

Replace ecm

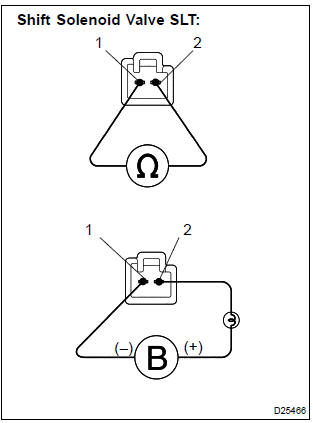

3 Inspect shift solenoid valve(slt)

- Remove the shift solenoid valve (slt).

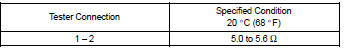

- measure the resistance according to the value(s) in the table below.

Standard:

- Connect the positive (+) battery lead with a 21 w bulb to the terminal 2 of the solenoid valve connector and the negative (–) battery lead to the terminal 1 of the solenoid valve connector for checking the solenoid valve operation.

Standard: the solenoid makes an operating noise.

Repair or replace transmission wire

Other materials:

Precaution

1. Notices when checking

power door lock/unlock function:

the wireless remote control function operates only when the following 3

conditions are met.

No key is inserted into the ignition key cylinder.

All the doors are closed. However, doors can be unlocked even wh ...

Pre–check

1. Srs warning light check

Turn the ignition switch to the on position and check that

the srs warning light lights up.

check that the srs warning light goes out after approx.

6 Seconds.

Hint:

when the ignition switch is at on and the srs warning

light remains on or flashes, the ...

Inspection procedure

1 Check operation(starter)

Check that the starter operates normally and that the engine starts.

2 Input signal check

See input signal check on page 05–745.

check the indicator light when shifting into except d position.

Ok:

the indicator light goes off when shifting ...