Toyota Corolla (E120): Inspection procedure

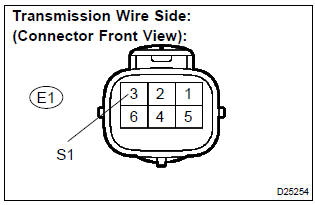

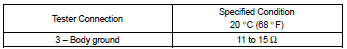

1 Inspect transmission wire(s1)

- Disconnect the transmission wire connector from the transaxle.

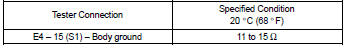

- measure the resistance according to the value(s) in the table below.

Standard:

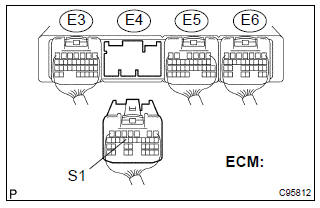

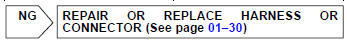

2 Check harness and connector(transmission wire – ecm)

- Connect the transmission connector to the transaxle.

- disconnect the connector from the ecm.

- measure the resistance according to the value(s) in the table below.

Standard:

Replace ecm

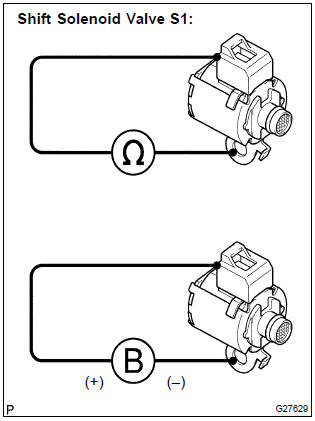

3 Inspect shift solenoid valve(s1)

- Remove the shift solenoid valve s1.

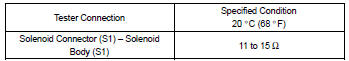

- measure the resistance according to the value(s) in the table below.

Standard:

- Connect the positive (+) battery lead to the solenoid connector terminal, and the negative (–) battery lead to the solenoid body for checking the solenoid valve operation.

Standard: the solenoid makes an operating noise.

Repair or replace transmission wire

Other materials:

Using the rear view monitor system

■ Screen description

1 Vehicle width guide lines

The line indicates a guide path when the vehicle is being backed straight up.

The displayed width is wider than the actual vehicle width.

2 Vehicle center guide lines

These lines indicate the estimated vehicle center on the ground.

3 Dis ...

Operating instructions

Turning the end of the lever turns on the lights as follows:

► Type A

1 The daytime running lights turn

on.

2 The side marker, parking, tail,

license plate, daytime running lights and instrument panel lights turn on.

3 The headlights and all the lights

listed above (except daytime ...

Problem symptoms table

Proceed to the reference page shown in the table below for each malfunction

symptom and troubleshoot

each circuit.

Hint:

troubleshooting of the tvip system is based on the premise that the door lock

control system and wireless

door lock control system is operating normally. Accordingly, be ...