Toyota Corolla (E120): Circuit description

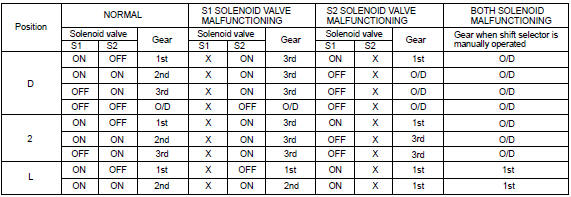

Shifting from 1st to o/d is performed in combination with on and off of the shift solenoid valve s1 and s2 controlled by ecm. If an open or short circuit occurs in either of the solenoid valves, the ecm controls the remaining normal solenoid valve to allow the vehicle to be operated smoothly (fail safe function).

Fail safe function: if either of the solenoid valve circuits develops an open or short, the ecm turns the other solenoid valve on and off to shift to the gear positions shown in the table below. If both solenoids malfunction, hydraulic control cannot be performed electronically and must be done manually.

Manual shifting as shown in the above table must be done (in the case of a short circuit, the ecm stops sending current to the short circuited solenoid).

X: malfunctions

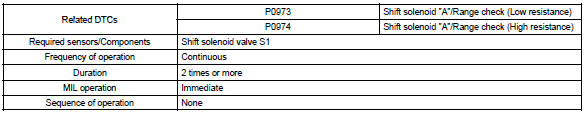

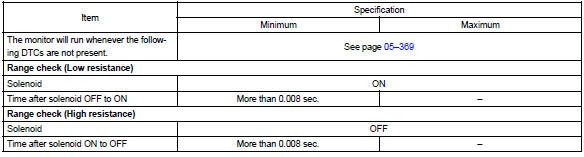

Monitor description

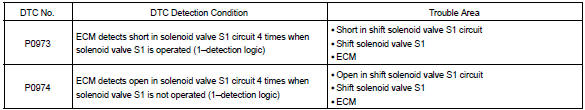

The ecm commands gearshift by turning the shift solenoid valves ”on/off”. When there is an open or short circuit in any shift solenoid valve circuit, the ecm detects the problem and the mil comes on. Illuminating the mil, the ecm performs the fail–safe and turns the other shift solenoid valves in good condition ”on/off” (in case of an open or short circuit, the ecm stops sending current to the circuit.).

Monitor strategy

Typical enabling condition

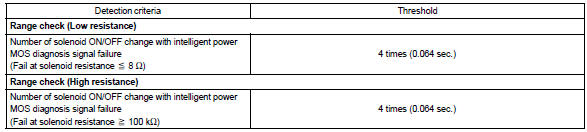

Typical malfunction thresholds

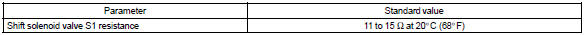

Component operating range

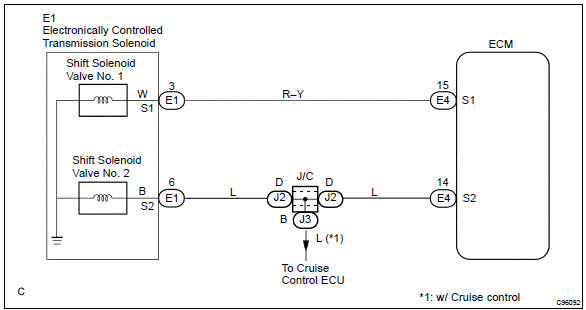

Wiring diagram

Other materials:

Heater control & accessory assy

Replacement

1. Remove console panel upper

2. Remove instrument cluster finish panel

3. Remove heater control & accessory assy

Release the 2 fitting claws and pull out the heater control

& accessory assy.

Using a screwdriver, open the claw of the cable clamp and

dis ...

Calibrating the compass

The direction display deviates from

the true direction determined by the earth’s magnetic field. The amount of deviation

varies according to the geographic position of the vehicle.

If you cross over a map boundary shown in illustration, the compass will deviate.

To obtain higher precision or ...

Replacement

Hint: components:

1. Discharge refrigerant from refrigeration system

sst 07110–58060 (07117–58080, 07117–58090, 07117–78050, 07117–88060,

07117–88070,

07117–88080)

2. Disconnect cooler refrigerant suction

hose no.1

Remove the bolt and disconnect the cooler refriger ...